The Future of Glass Reinforced Polymer.

Glass Reinforced Polymer.

1.Introduction.

Glass Reinforced Polymer (GRP) is a revolutionary material that has been making waves in various industries. Let’s delve into the intricacies of this composite material, unlocking its potential for a myriad of applications.Glass Reinforced Polymer, commonly known as GRP, is a composite material composed of a polymer matrix reinforced with glass fibers. This dynamic combination results in a material that possesses remarkable strength, durability, and versatility.GRP comprises a polymer matrix, often epoxy or polyester, interwoven with glass fibers. The meticulous arrangement of these fibers imparts exceptional mechanical properties to the material, making it a preferred choice in industries ranging from construction to automotive.

2.Composition of Glass-Reinforced Polymer

2.1The Core: Fiberglass

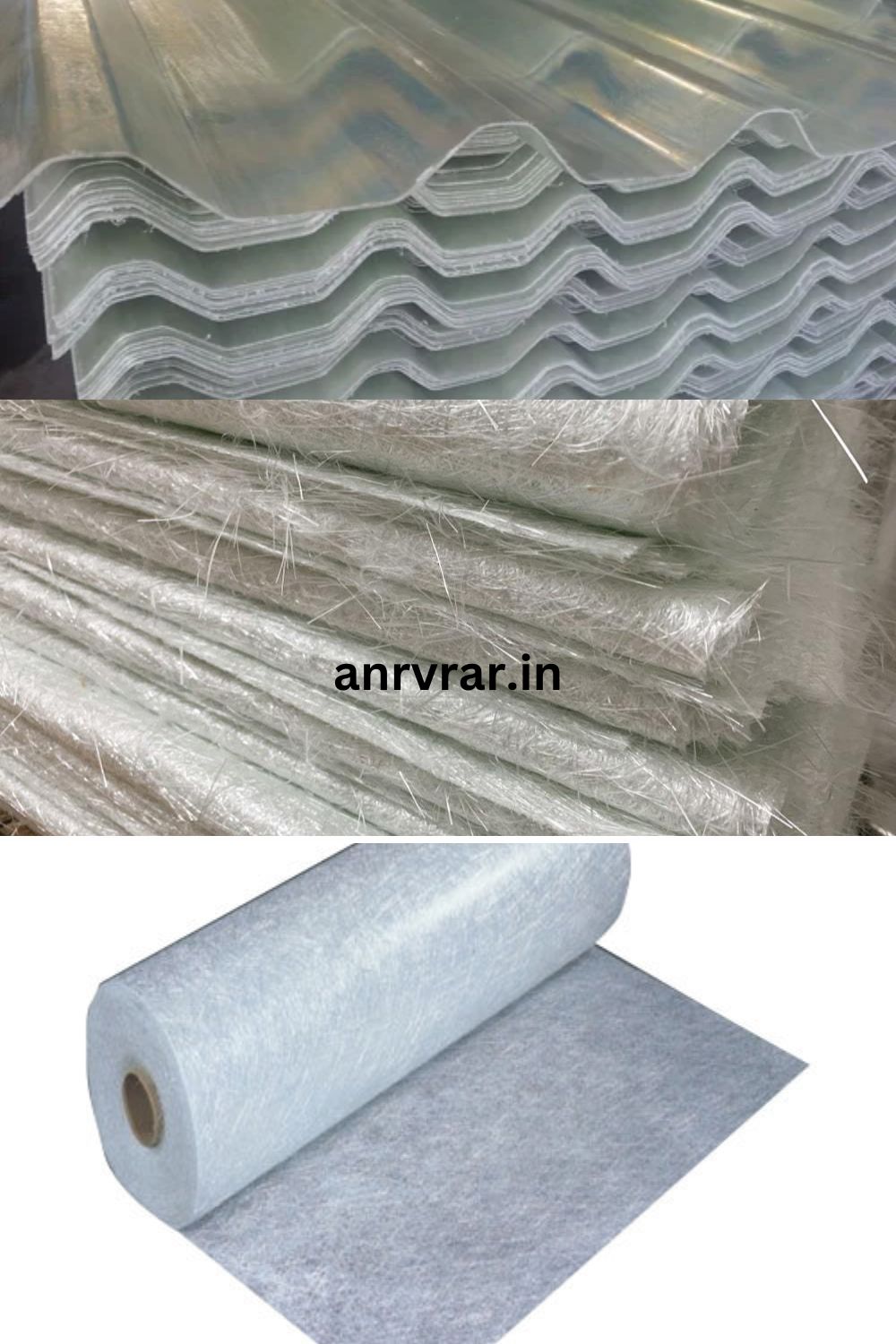

At the heart of Glass-Reinforced Polymer lies fiberglass – a resilient and lightweight material composed of thin fibers of glass. These fibers, often woven together, create a matrix that contributes to the composite’s robust structure.

2.2The Binding Force: Polymer Matrix

Complementing the fiberglass, the polymer matrix serves as the binding force. Typically, thermosetting resins like epoxy or polyester are used. This matrix not only binds the fibers but also enhances the material’s overall durability.

2.3Fiber Orientation Matters

One key factor influencing GRP’s performance is the orientation of the fiberglass within the matrix. Manufacturers strategically align the fibers to optimize strength and rigidity, ensuring the material can withstand diverse stresses.

2.4Tailored for Purpose

The beauty of Glass-Reinforced Polymer lies in its adaptability. Engineers can customize the composition to meet specific requirements, tailoring the material for a myriad of applications, from automotive components to architectural elements.

3.Manufacturing Process

3.1Crafting Brilliance

The manufacturing journey commences with meticulous planning and raw material selection. A precise blend of glass fibers and polymer resins lays the foundation for GRP’s exceptional properties. This crucial step sets the stage for what follows.

3.2Weaving Strength

To fortify the composite, glass fibers undergo a strategic weaving process, intertwining them with precision. This not only enhances structural integrity but also contributes to GRP’s remarkable durability – a testament to the meticulous craftsmanship involved.

3.3Polymer Resin Integration

As the glass fibers take their place, polymer resins enter the scene, orchestrating a chemical dance that culminates in a powerful bond. This fusion is pivotal, ensuring the GRP’s ability to withstand the test of time and environmental challenges.

3.4Shaping the Future

Once the composite is ready, it’s time for molding – a transformative stage that gives GRP its final form. Molds, meticulously designed and crafted, play a crucial role in shaping everything from automotive components to architectural marvels.

3.5Precision Curing

Curing, the final frontier in GRP production, involves subjecting the molded components to controlled temperatures. This process enhances the material’s strength, ensuring it emerges resilient and ready to tackle the demands of various industries.

4.Applications

4.1Sailing into the Future: GRP’s Maritime Applications

Delving into the maritime world, GRP proves its mettle in boat building and marine engineering. Its lightweight nature coupled with exceptional strength makes it a preferred choice for crafting seaworthy vessels that navigate the toughest waters with ease.

4.2GRP’s Role in Automotive Design

The automotive industry is no stranger to innovation, and GRP stands at the forefront of this revolution. From enhancing vehicle aesthetics to contributing to fuel efficiency, GRP is steering the automotive design landscape into a new era.

4.3Sculpting Possibilities

Beyond structural applications, GRP finds a place in the realm of art and design. Sculptors and artists leverage its malleability to create intricate masterpieces that seamlessly blend form and function.

5.Advantages of Glass-Reinforced Polymer

5.1Breaking Ground

GRP, commonly known as fiberglass, stands at the forefront of innovation in material science. Comprising glass fibers embedded in a polymer matrix, it fuses the strength of glass with the flexibility of polymers, creating a composite material with exceptional properties.

5.2Bold and Beautiful

Beyond its structural prowess, GRP boasts a sleek and visually appealing facade. The material’s adaptability allows for intricate designs and seamless integration into diverse architectural styles. Businesses and homeowners alike are drawn to the aesthetic charm that GRP brings to the table.

5.3Strength-to-Weight Ratio

One of the most compelling advantages of GRP lies in its remarkable strength-to-weight ratio. Unlike traditional materials, GRP offers robust structural support without adding unnecessary weight. This not only simplifies transportation and installation but also enhances the overall efficiency of structures.

5.4Corrosion Resistance

GRP’s inherent resistance to corrosion sets it apart in environments prone to moisture and harsh weather conditions. Unlike metals that succumb to rust, GRP remains steadfast, ensuring longevity and minimal maintenance requirements. Industries such as marine and chemical processing find solace in GRP’s ability to endure corrosive challenges.

5.6Eco-Friendly Innovation

As sustainability takes center stage, GRP aligns itself as an eco-friendly alternative. With a production process that consumes less energy compared to traditional materials, GRP champions environmental responsibility without compromising on performance. Businesses aiming for a green footprint find GRP to be a conscientious choice.

5.7Seamless Integration in Various Industries

From aerospace to construction, GRP seamlessly integrates into a myriad of industries. Its adaptability, coupled with the ease of molding into complex shapes, positions GRP as the material of choice for diverse applications. The automotive sector, in particular, leverages GRP for lightweight yet robust components.

6.Challenges in Usage

6.1.Challenge

6.1.1.Addressing Durability Head-On

GRP, while robust, can face durability concerns, especially in harsh environmental conditions. UV exposure and extreme temperatures may impact its longevity. To counter this, manufacturers are investing in advanced coatings and formulations, enhancing GRP’s resilience against external elements.

6.1.2.Balancing Act: Achieving Optimal Weight and Strength

The weight-to-strength ratio is a critical consideration in many applications. Balancing these factors is challenging, but ongoing research focuses on optimizing the composition of Glass-Reinforced Polymer to achieve the ideal equilibrium. This ensures that the material remains lightweight without compromising its structural integrity.

6.1.3.Joining Challenges

Connecting GRP components can be intricate, impacting the overall structural integrity. Innovations in bonding technologies and adhesives are actively addressing this challenge, providing secure and durable joins that meet the stringent requirements of various industries.

6.2.Solutions

6.2.1Advanced Coatings

To combat durability concerns, manufacturers are incorporating cutting-edge coatings that shield GRP from environmental stressors. These coatings not only enhance the material’s lifespan but also contribute to its aesthetic appeal.

6.2.2Nano-Enhanced Formulations

Researchers are delving into nanotechnology to develop formulations that bolster the inherent properties of Glass-Reinforced Polymer. By integrating nanomaterials, they aim to fortify GRP against external factors, ensuring it remains a reliable choice in demanding conditions.

6.2.3Bonding Innovations

Addressing the joining difficulties, advancements in bonding technologies are revolutionizing the way GRP components are interconnected. These innovations not only streamline the manufacturing process but also enhance the structural integrity of the final product.https://gripclad.co.uk/useful-information/what-is-grp/

FAQs

Can glass-reinforced polymer be recycled?

Yes, glass-reinforced polymer can be recycled, contributing to sustainable practices in manufacturing.

How does the cost of using glass-reinforced polymer compare to traditional materials?

While initial costs may be higher, the long-term benefits, such as durability and reduced maintenance, often justify the investment.

Are there any limitations to the shapes that can be molded using glass-reinforced polymer?

Glass-reinforced polymer offers flexibility in molding, but intricate shapes may pose challenges.

What industries benefit the most from using glass-reinforced polymer?

Industries such as automotive, construction, and aerospace find significant advantages in utilizing glass-reinforced polymer.

How can manufacturers address environmental concerns associated with glass-reinforced polymer production?

Adopting eco-friendly production methods and exploring green alternatives are key steps in mitigating environmental impact.