Polypropylene Fiber-Manufacturing Process

Polypropylene Fiber

Introduction of Polypropylene Fiber.

Polypropylene fiber is a versatile synthetic fiber derived from the polymerization of propylene, a thermoplastic polymer. It is known for its exceptional strength, durability, and a wide range of applications across various industries. This fiber is a type of polyolefin and is often used as a textile material due to its unique combination of properties.

What is Polypropylene Fiber.?

Polypropylene is a thermoplastic polymer that is widely used in various applications due to its versatility and desirable properties. It is a type of plastic that belongs to the polyolefin group, which also includes polyethylene. Polypropylene is produced through the polymerization of propylene monomers.

Characteristics of polypropylene.

Polypropylene is a linear hydrocarbon polymer, with a repeating unit composed of propylene monomers.It is a linear structure based on the monomer CnH2n. It is manufactured from propylene gas in presence of a catalyst such as titanium chloride. Its chemical formula is (C3H6)n, where n represents the number of repeating units in the polymer chain.

Polypropylene is known for its high melting point, making it suitable for applications requiring heat resistance.

It has a relatively low density, making it lightweight and useful in manufacturing lightweight products.

It is resistant to moisture, chemicals, and many solvents

MANUFACTURING PROCESS OF POLYPROPYLENE FIBER

The manufacturing process of polypropylene fiber or filament involves several steps. Polypropylene is a thermoplastic polymer that is commonly used in the production of synthetic fibers due to its excellent properties such as high strength, low density, and chemical resistance. Here is a general overview of the manufacturing process:

Polymerization:

The process starts with the polymerization of propylene monomers. Propylene gas is polymerized using a catalyst to form polypropylene resin.

Extrusion:

The polypropylene resin is then melted and extruded through a spinneret, which is a device with fine holes or slits. The spinneret shapes the molten polypropylene into fibers of the desired diameter.

Cooling and Solidification:

As the extruded fibers pass through the spinneret, they are cooled rapidly to solidify the polypropylene. This can be achieved through air quenching or other cooling methods.

Drawing or Orientation:

The solidified fibers may undergo a drawing or orientation process. During drawing, the fibers are stretched to align the polymer chains, which increases their strength and stiffness. This step is crucial for enhancing the mechanical properties of the polypropylene fibers.

Heat Setting:

The drawn fibers are then heat-set to relieve internal stresses and lock in the orientation achieved during the drawing process. This step ensures that the fibers maintain their desired properties.

Cutting and Packaging:

After heat setting, the continuous filaments are cut into staple fibers of the desired length or left as continuous filaments, depending on the intended use. The fibers are then packaged for distribution.

PHYSICAL PROPERTIES OF POLYPROPYLENE FIBER

Tensile strength of polypropylene fiber

The tensile strength of polypropylene fiber is typically measured in units of grams-force per denier (gf/den). Denier is a unit of measurement for the linear mass density of fibers, equal to the mass in grams per 9,000 meters. Tensile strength is a measure of the maximum load a material can withstand when being stretched or pulled before breaking.

The specific tensile strength of polypropylene fiber can vary depending on the manufacturing process, the type of polypropylene used, and other factors. typical tensile strengths for polypropylene fiber can range from around 3.5 to 5.5 grams-force per denier (gf/den).

Elongation of POLYPROPYLENE FIBER

Polypropylene fiber, like other synthetic fibers, undergoes elongation under certain conditions. Elongation refers to the ability of a material to stretch or extend without breaking. In the case of polypropylene fiber, its elongation properties are influenced by factors such as temperature, strain rate, and the presence of external forces.

Temperature:

Polypropylene fibers generally have a higher elongation at elevated temperatures. As the temperature increases, the molecular mobility of the polymer chains also increases, allowing the fibers to stretch more easily. However, it’s essential to consider the specific temperature range within which polypropylene maintains its structural integrity.Melting point (ºC) of Polypropylene fiber is 165

Strain Rate:

The rate at which a force is applied to the polypropylene fiber, known as the strain rate, affects its elongation behavior. Higher strain rates often result in lower elongation, as the fibers may not have enough time to rearrange and accommodate the applied stress.

Tensile strength 3.7 to 5.7(gf/den)

Chemical resistance Excellent

Electric insulation Good

Elongation 40 to 80(%)

Melting point 165 (ºC)

Moisture absorption 0 to 0.02(%)

THERMAL PROPERTIES of POLYPROPYLENE FIBER

Polypropylene fiber, a versatile material, exhibits several notable thermal properties that contribute to its widespread use in various applications:

Low Thermal Conductivity:

Polypropylene fiber possesses low thermal conductivity, meaning it is a poor conductor of heat. This property makes it useful in applications where insulation is required, such as in clothing and thermal barriers.

Melting Point:

Polypropylene has a relatively high melting point, typically ranging from 320 to 340 degrees Fahrenheit (160 to 171 degrees Celsius). This property makes it suitable for applications where exposure to elevated temperatures is a consideration.

Heat Resistance:

Polypropylene fibers demonstrate good heat resistance, allowing them to maintain their structural integrity and performance in environments with elevated temperatures.

Thermal Stability:

The material exhibits thermal stability over a broad temperature range, providing durability and reliability in various conditions.

Resilience to Thermal Stress:

Polypropylene fibers can withstand thermal stress without undergoing significant deformation or degradation, contributing to their longevity in different applications.

Low Thermal Expansion:

Polypropylene has low thermal expansion characteristics, meaning it undergoes minimal dimensional changes when exposed to temperature variations. This property is advantageous in applications where stability and precision are crucial.

ADVANTAGES OF POLYPROPYLENE FIBERS.

Polypropylene fibers offer several advantages in various applications due to their unique properties. Here are some of the key advantages of polypropylene fibers:

Lightweight:

Polypropylene fibers are lightweight, making them easy to handle and transport. This property is particularly beneficial in applications where weight is a critical factor, such as in textiles and construction materials.

Chemical Resistance:

Polypropylene is resistant to many chemicals, including acids and bases. This makes it suitable for use in environments where exposure to various chemicals is a concern.

Water Resistance:

Polypropylene fibers are hydrophobic, meaning they repel water. This makes them ideal for use in applications where resistance to moisture is important, such as in outdoor textiles or geotextiles.

High Tensile Strength:

Polypropylene fibers have high tensile strength, providing durability and strength in various applications. This property is particularly advantageous in industries like construction and geotechnical engineering.

Abrasion Resistance:

Polypropylene fibers exhibit good resistance to abrasion, making them suitable for applications where materials may be subjected to wear and tear over time.

Inertness:

Polypropylene is inert and does not react with other materials. This makes it suitable for use in applications where chemical reactions with the surrounding environment need to be minimized.

Low Thermal Conductivity:

Polypropylene has low thermal conductivity, which means it provides good insulation. This property is advantageous in applications where thermal insulation is required, such as in clothing or certain building materials.

Recyclability:

Polypropylene is recyclable, contributing to sustainability efforts and reducing environmental impact.

Cost-Effective:

Polypropylene is generally cost-effective compared to some other materials with similar properties. This makes it a preferred choice in various industries where cost considerations are crucial.

DISADVANTAGES OF POLYPROPYLENE FIBERS

Polypropylene fibers, like any material, have their disadvantages. Here are some drawbacks associated with polypropylene fibers:

Low Melting Point:

Polypropylene fibers have a relatively low melting point compared to some other synthetic fibers. This means they can deform or melt when exposed to high temperatures, limiting their use in applications where heat resistance is crucial.

Flammability:

While polypropylene has a high melting point, it is still a flammable material. In the presence of a flame, polypropylene fibers can melt and contribute to the spread of fire.

Limited Resistance to Chemicals:

Polypropylene fibers may not be as resistant to certain chemicals as some other synthetic fibers. Exposure to certain solvents and chemicals can result in degradation and loss of strength.

Poor Adhesion Properties:

Polypropylene fibers may have poor adhesion properties when it comes to bonding with other materials. This can limit their use in applications where strong bonding is essential.

Limited Dye Affinity:

Polypropylene fibers may not readily accept dyes, resulting in limitations in color options. This can be a disadvantage in applications where color customization is important.

Not Biodegradable:

Polypropylene is not biodegradable, which can contribute to environmental concerns. Improper disposal of products made from polypropylene fibers can lead to long-lasting environmental impact.

Low Elasticity:

Polypropylene fibers have lower elasticity compared to some other synthetic fibers. This may affect their performance in applications where elasticity and flexibility are crucial.

Poor Insulation Properties:

Polypropylene fibers may have poor insulation properties, especially in terms of heat insulation. This can be a limitation in applications where thermal insulation is a critical factor.

USES and APPLICATIONS OF POLYPROPYLENE FIBERS

Textiles and Apparel:

Polypropylene fibers are often used in the textile industry to make a variety of fabrics, including clothing, home textiles, and industrial textiles. The fibers are lightweight, durable, and resistant to stains and moisture.

Geotextiles:

Polypropylene fibers are widely used in the construction industry as geotextiles. These materials are used for soil stabilization, erosion control, and reinforcement in civil engineering projects such as road construction, embankments, and retaining walls.

Packaging:

Polypropylene fibers are used in the manufacturing of packaging materials, including woven bags, sacks, and flexible packaging. The fibers provide strength, durability, and moisture resistance to the packaging.

Automotive Applications:

In the automotive industry, polypropylene fibers are used for various applications, such as interior trims, upholstery, and carpeting. The fibers contribute to lightweight and durable components.

Medical Textiles:

Polypropylene fibers are utilized in the medical field for the production of non-woven fabrics used in surgical gowns, masks, and other disposable medical products. The fibers are often chosen for their hypoallergenic and sterilizable properties.

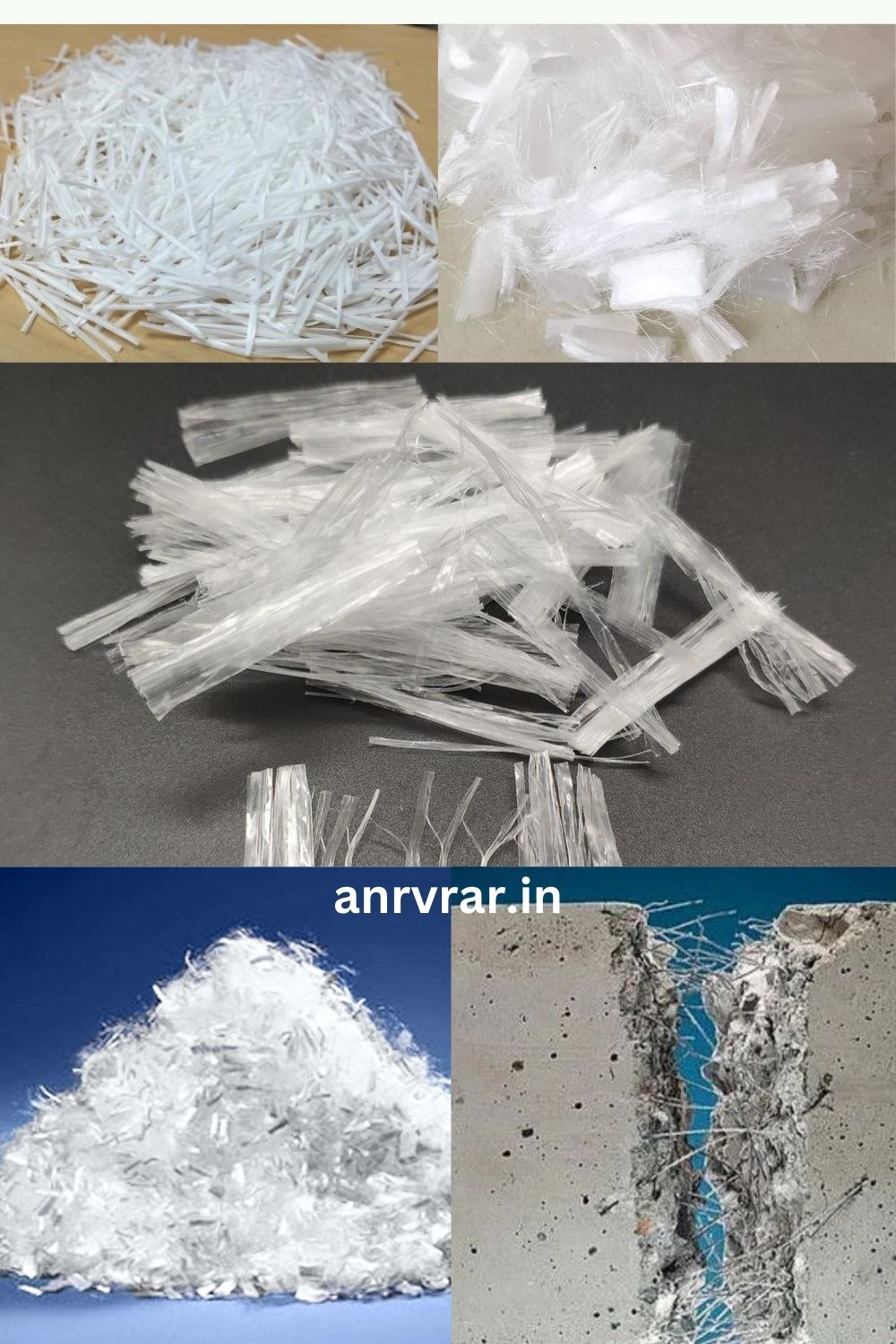

Concrete Reinforcement:

Polypropylene fibers are added to concrete to improve its tensile strength and reduce cracking. These fibers help control shrinkage cracks and enhance the overall durability of the concrete.

Filtration:

Due to its chemical resistance and inert nature, polypropylene fibers are used in the manufacturing of filters for air, water, and other fluids. These filters are widely used in industries and households.

Rope and Twine:

Polypropylene fibers are commonly used in the production of ropes and twines due to their strength and resistance to abrasion. These ropes find applications in various industries, including agriculture and marine.

Sports Equipment:

Polypropylene fibers are incorporated into sports equipment such as nets, ropes, and sports bags due to their lightweight and durable nature.

Industrial Applications:

Polypropylene fibers find applications in various industrial settings, including conveyor belts, insulation, and protective clothing, where their unique combination of properties is advantageous.

https://textilelearner.net/polypropylene-fiber-properties-applications/