Polymer Fiber,Types of Polymer Fiber

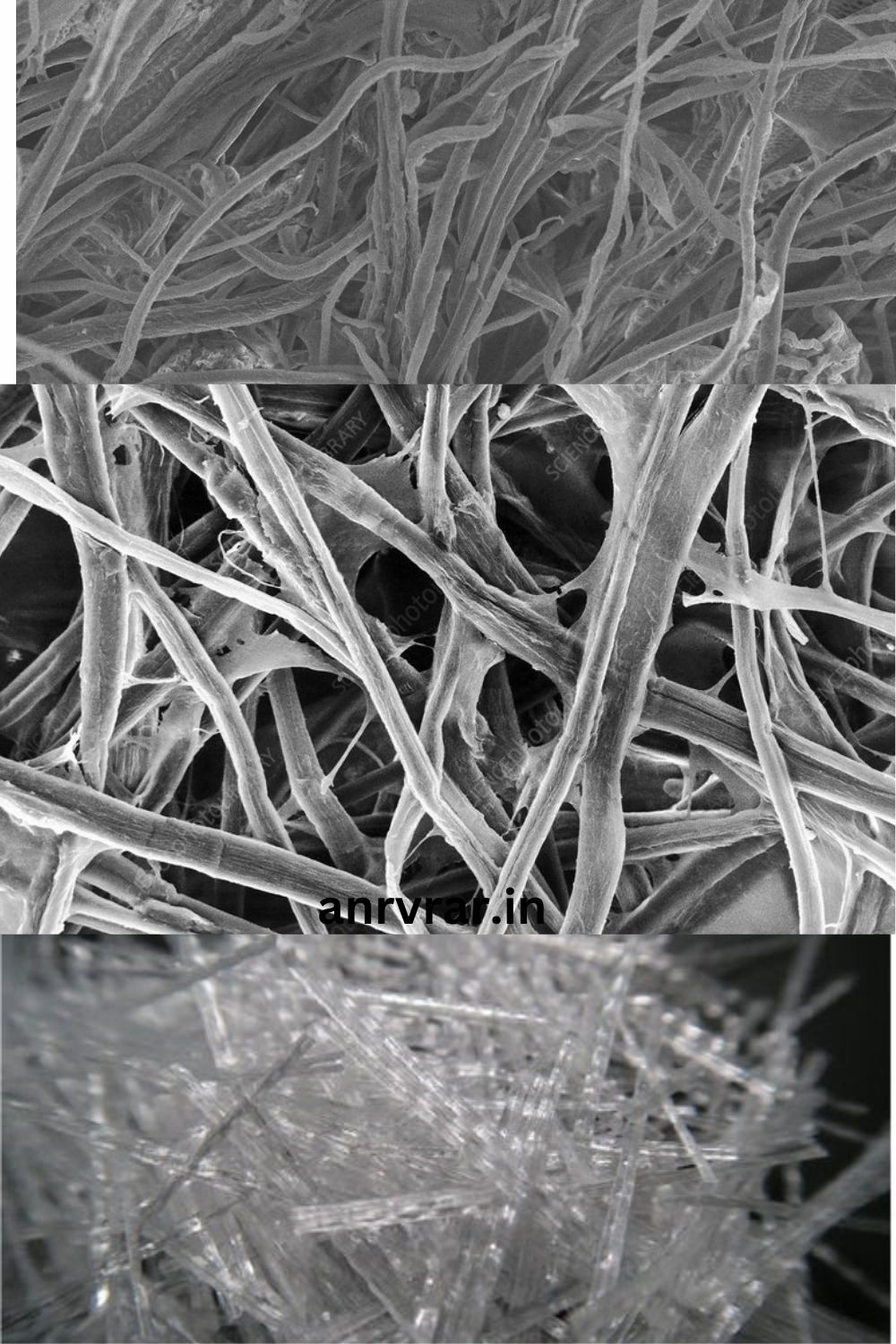

Polymer Fiber

Introduction.

In today’s fast-paced world, where sustainability is paramount, the spotlight is turning towards innovative materials that can revolutionize industries. Polymer fiber, a cutting-edge material, is at the forefront of this revolution, promising a myriad of applications across various sectors.Polymer fiber, a versatile and resilient material, has become a game-changer in the realm of materials science. Derived from synthetic polymers, it boasts exceptional strength and durability, making it an ideal candidate for a wide array of applications.One of the key reasons behind the growing popularity of polymer fiber is its eco-friendly nature. Unlike traditional materials, polymer fiber is recyclable and reduces the carbon footprint, aligning seamlessly with the global push for sustainable practices.

Types of Polymer Fiber

1. Polyethylene Terephthalate (PET) Fiber

PET fibers, renowned for their durability and resistance to moisture, find extensive use in the textile industry. From clothing to carpets, PET fibers dominate the market, offering a perfect blend of strength and flexibility.

2. Nylon Fiber: A Powerhouse of Strength

Nylon, a synthetic polymer, stands out for its exceptional strength and elasticity. Widely utilized in manufacturing fabrics, ropes, and industrial materials, nylon fibers contribute to the robustness of various end products.

3. Polypropylene Fiber for Versatility

Polypropylene fibers boast versatility, making them suitable for a broad range of applications. Their resistance to chemicals and moisture makes them ideal for use in geotextiles, packaging, and medical textiles.

4. Rayon Fiber: The Natural Synthetic

Although derived from natural sources like wood pulp, rayon is categorized as a synthetic fiber. Known for its silk-like feel, rayon fibers are commonly used in textiles, blending comfort with affordability.

Manufacturing Process

1.Raw Materials Selection

The foundation of exceptional polymer fibers lies in the careful selection of raw materials. Polymers, with their unique chemical compositions, become the building blocks. These materials, sourced with precision, set the stage for the subsequent steps in the manufacturing process.

2.Polymerization

Boldly stepping into the polymerization process, raw materials undergo a transformative dance of chemical reactions. This pivotal stage involves linking monomers, creating long chains of polymers. The precision in this synthesis is paramount, ensuring the desired characteristics of the final polymer fiber.

3.Extrusion Process

As the polymerization concludes its chemical symphony, the next act unfolds in the extrusion process. Here, the polymer melt is meticulously pushed through spinnerets, forming continuous filaments. The size and shape of these spinnerets play a crucial role in determining the properties of the resulting fiber.

4.Solidification

In the wake of extrusion, the freshly formed polymer filaments enter a zone of controlled cooling. This solidification process is a delicate balance, shaping the molecular structure and, consequently, the physical attributes of the fiber. Precision is paramount to achieving the desired strength and flexibility.

5.Drawing the Strands

The drawn-out process follows, where the polymer strands undergo controlled stretching. This imparts additional strength and alignment to the fibers, creating a robust structure. The degree of drawing significantly influences the mechanical properties of the final product.

6.Additives and Modifications

In the ever-evolving landscape of polymer fiber manufacturing, additives and modifications introduce a layer of sophistication. These may include colorants, flame retardants, or reinforcing agents, enhancing the fiber’s performance and expanding its range of applications.

7.Quality Control

Before reaching the market, stringent quality control measures ensure that each batch meets exacting standards. Testing for tensile strength, durability, and other key parameters guarantees the reliability and consistency of the polymer fibers.

Properties of Polymer Fiber

1.Tensile Strength of Polymer Fiber

Polymer fiber stands tall with its exceptional tensile strength, making it a prime choice for applications demanding durability and resilience. Whether reinforcing composite materials or enhancing the structural integrity of a product, the robust tensile strength of polymer fiber remains unparalleled.

2.Polymer Fiber’s Bendability

One of the standout attributes of polymer fiber is its inherent flexibility. This quality not only facilitates the ease of handling during manufacturing processes but also opens doors to innovative designs in industries such as textiles and construction. The bendability of polymer fiber creates opportunities for groundbreaking solutions in diverse applications.

3.Polymer Fiber’s Low Density Advantage

In the realm of materials, density plays a pivotal role, and polymer fiber emerges victorious with its low-density characteristic. This unique feature not only contributes to lightweight end products but also makes polymer fiber an eco-friendly alternative, aligning with the contemporary emphasis on sustainability.

4.Polymer Fiber’s Impressive Weather Resistance

Polymer fiber’s resistance to harsh weather conditions positions it as an ideal choice for outdoor applications. From outdoor furniture to geotextiles, the ability of polymer fiber to withstand environmental challenges ensures longevity and reliability in various scenarios.

Applications

1.The Role of Polymer Fiber in Construction

Polymer fiber has become a cornerstone in the construction industry, reinforcing the very foundations upon which structures stand. As a resilient and durable material, it adds strength to concrete, ensuring structures withstand the test of time. The incorporation of polymer fiber minimizes the risk of cracks and enhances the overall structural integrity of buildings, bridges, and other infrastructural marvels.

2.Polymer Fiber in Electronics

In the realm of electronics, where precision and reliability are paramount, polymer fiber takes center stage. Its lightweight and flexible nature make it an ideal candidate for weaving through the intricate pathways of electronic devices. This not only enhances the performance of electronic components but also contributes to the development of sleeker and more efficient gadgets.

3.Polymer Fiber in Fashion and Design

Polymer fiber isn’t confined to the realm of functionality; it also makes a bold statement in the world of fashion and design. From futuristic apparel to avant-garde accessories, designers are harnessing the versatility of polymer fiber to create unique and visually stunning pieces. Its adaptability allows for the crafting of garments that seamlessly blend style with comfort.

4.Polymer Fiber in Environmental Initiatives

As the world embraces the need for sustainable practices, polymer fiber emerges as a champion in environmental initiatives. Its recyclable nature and eco-friendly characteristics make it an attractive choice for industries looking to reduce their carbon footprint. From packaging materials to eco-conscious textiles, polymer fiber is paving the way for a greener, more sustainable future.

Advantages and Disadvantages

Advantages of Polymer Fiber

1.Lightweight

Polymer fibers boast an extraordinary lightweight characteristic, making them an ideal choice for applications where reducing overall weight is crucial. From aerospace engineering to wearable technology, the weight advantage of polymer fibers enhances performance and user experience.

2.Durability

One of the standout features of polymer fibers is their exceptional durability. These fibers exhibit a high resistance to wear and tear, ensuring longevity in diverse environments. Industries relying on robust materials find solace in the durability of polymer fibers, contributing to the overall reliability of the end product.

3.Corrosion Resistance

Unlike traditional materials, polymer fibers showcase remarkable resistance to corrosion. This property proves invaluable in harsh environments where exposure to corrosive elements could compromise the structural integrity of materials. Polymer fibers, acting as a shield against corrosion, contribute to the longevity of products.

4.Cost-Effective Solution

In a world where cost-effectiveness is a critical consideration, polymer fibers emerge as a viable solution. The manufacturing process of polymer fibers is often more economical compared to traditional materials, making them an attractive choice for budget-conscious projects.

Disadvantages of Polymer Fiber

1.Environmental Concerns

Despite their impressive qualities, polymer fibers raise environmental concerns. The production and disposal of these synthetic materials contribute to pollution and environmental degradation. As the world shifts towards sustainability, addressing these concerns becomes paramount for the widespread acceptance of polymer fibers.

2.Limited Heat Resistance

Polymer fibers, while excelling in many areas, may falter when it comes to heat resistance. In applications where exposure to high temperatures is a constant, alternative materials with superior heat resistance might be preferred.

3.UV Radiation

Excessive exposure to UV radiation can affect the structural integrity of polymer fibers over time. Industries requiring materials with prolonged outdoor exposure must carefully consider this aspect and implement protective measures to mitigate the impact of UV radiation.

4.Dependency on Petroleum-Based Resources

The production of polymer fibers is heavily reliant on petroleum-based resources. As the world seeks sustainable alternatives, this dependence on non-renewable resources becomes a notable drawback, prompting exploration into eco-friendly alternatives.

Advantages of Polymer Fiber

1.Structural Integrity with Polymer Fiber

In the realm of construction materials, structural integrity is non-negotiable. Polymer Fiber emerges as a game-changer, significantly enhancing the durability and strength of structures. Its unique composition ensures unparalleled support, making it an ideal choice for projects demanding resilience and longevity.

2.The Weight Advantage

One of the standout features of Polymer Fiber is its remarkable strength-to-weight ratio. This lightweight material doesn’t compromise on robustness, making it easier to handle during construction. As the industry increasingly values efficiency, Polymer Fiber’s weight advantage is a boon for builders seeking both strength and ease of use.

3.Polymer Fiber’s Impressive Flexibility

Flexibility is a virtue, especially in construction. Polymer Fiber, with its inherent flexibility, provides structures with the ability to withstand external pressures, be it seismic activity or natural wear and tear. This resilience ensures that buildings endure the test of time, maintaining their form and function.

4.Eco-Friendly Construction

In an era where sustainability is paramount, Polymer Fiber stands tall as an eco-friendly alternative. Its production requires fewer resources compared to traditional construction materials, contributing to a greener environment. Choosing Polymer Fiber aligns with the global shift towards sustainable construction practices.

5.Polymer Fiber’s Long-Term Benefits

Investing in Polymer Fiber isn’t just about the present; it’s about future-proofing infrastructure. The material’s resistance to corrosion and degradation ensures that structures remain steadfast against the forces of nature. This longevity translates to reduced maintenance costs and increased overall value.

Limitations and Challenges of Polymer Fiber

1. Durability Dilemma

Crafting polymer fibers with enhanced durability is crucial. The inherent challenge lies in maintaining strength without compromising flexibility. Innovative solutions are on the horizon, promising a breakthrough in addressing this durability dilemma.

2. Environmental Impact

As the world leans towards sustainability, polymer fiber faces scrutiny for its environmental impact. Strategies such as recycling programs and eco-friendly production processes are imperative to mitigate this concern, aligning the material with contemporary eco-conscious values.

3. Cost Conundrum

The cost-effectiveness of polymer fibers poses a challenge for widespread adoption. Research and development efforts are actively focused on streamlining production processes and raw material costs, paving the way for a more economically viable future.

4. Innovative Research and Development

To conquer the limitations of polymer fiber, ongoing research and development play a pivotal role. Investing in cutting-edge technologies and methodologies ensures a continuous evolution, addressing challenges head-on.

5. Collaborative Industry Initiatives

Tackling challenges collectively enhances the industry’s ability to innovate. Collaborative initiatives foster a shared pool of knowledge, propelling polymer fiber into new realms of possibility.

6. Educational Advocacy

Overcoming challenges requires widespread awareness and understanding. Educational advocacy programs aim to enlighten industries, policymakers, and the general public about the immense potential of polymer fiber, fostering a supportive environment for its growth.https://en.wikipedia.org/wiki/Fiber#:~:text=Polymer%20fibers%20are%20a%20subset,phenol%2Dformaldehyde%20(PF)

FAQs

1.Is Polymer Fiber Environmentally Friendly?

Yes, Polymer Fiber can be environmentally friendly. Many variations are recyclable, contributing to sustainable practices. However, it’s crucial to check the specific type and manufacturing process for eco-friendly options.

2.How does Polymer Fiber Compare to Traditional Materials?

Polymer Fiber often surpasses traditional materials in terms of strength, durability, and weight. Its lightweight nature coupled with impressive strength makes it a preferred choice in various industries.

3.Can Polymer Fiber be Recycled?

Absolutely. Many Polymer Fiber variants are recyclable, reducing environmental impact. Recycling processes vary, so it’s advisable to follow guidelines specific to the type of polymer used.

4.What Industries Benefit Most from Polymer Fiber?

Polymer Fiber finds applications across a spectrum of industries. Notable beneficiaries include textiles, construction, automotive, and aerospace, where its unique properties address specific needs.

5.Are There Different Types of Polymer Fiber?

Yes, Polymer Fiber comes in various types, each tailored for specific applications. Examples include aramid fibers known for their flame resistance and ultra-high-molecular-weight polyethylene for exceptional strength.