Polycyclohexylenedimethylene Terephthalate(PCDT Polyester)

Polycyclohexylenedimethylene Terephthalate (PCDT Polyester)

Introduction of Polycyclohexylenedimethylene Terephthalate(PCDT Polyester)

Polycyclohexylenedimethylene terephthalate, commonly known as PCDT polyester, is a type of thermoplastic polymer with unique properties that make it suitable for various applications. This polyester is synthesized through the condensation polymerization of cyclohexanedimethanol and terephthalic acid or its ester derivatives.

One notable characteristic of PCDT polyester is its high melting point, which contributes to its thermal stability and resistance to heat. This makes it particularly advantageous in applications where exposure to elevated temperatures is a concern. Additionally, PCDT polyester exhibits excellent chemical resistance, making it resistant to many solvents and chemicals.

The polymer’s molecular structure includes cyclohexane rings, which contribute to its distinctive properties. These rings enhance the polymer’s overall strength and dimensional stability. PCDT polyester is also known for its durability and resistance to wear and abrasion, making it suitable for applications requiring long-lasting materials.

Common uses of PCDT polyester include the production of fibers for textiles, industrial belting, and technical fabrics. Its high-performance characteristics make it a preferred choice in applications where strength, resistance to heat, and chemical stability are crucial. As technology and material science continue to advance, PCDT polyester may find new and innovative applications across various industries.

Chemical Composition of Polycyclohexylenedimethylene terephthalate(PCDT Polyester)

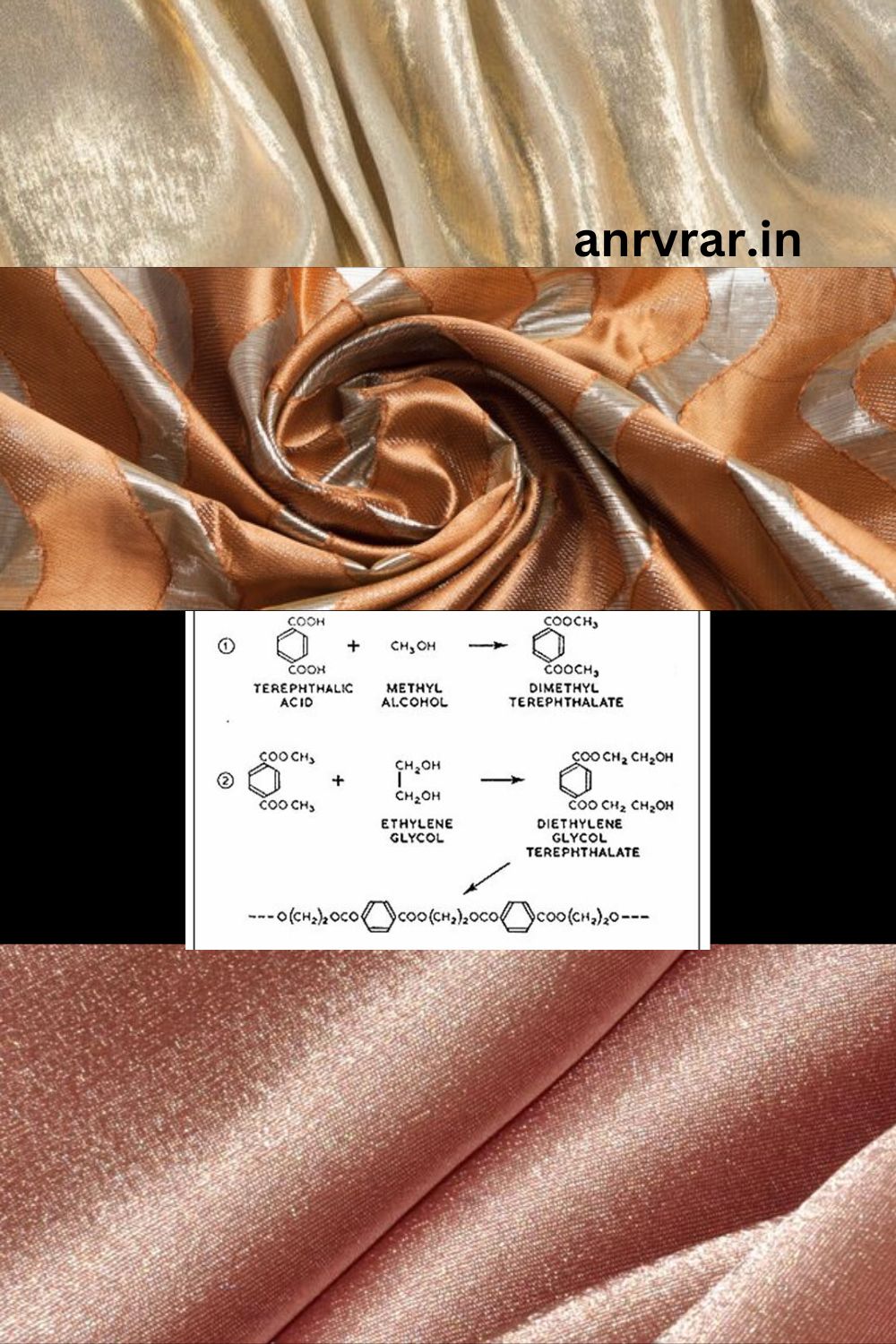

Polycyclohexylenedimethylene terephthalate (PCDT polyester) is a type of polyester polymer. The chemical composition of PCDT polyester can be described by its monomer units. In this case, PCDT polyester is derived from two main monomers:

Polycyclohexylenedimethylene glycol.

This is a diol (two alcohol functional groups) derived from cyclohexane. The chemical structure of Polycyclohexylenedimethylene glycol is:

HO-CH2−C6H10−CH2−OHHO-CH2−C6H10−CH2−OH

Terephthalic acid.

This is a dicarboxylic acid. The chemical structure of terephthalic acid is:

C6H4(COOH)2C6H4(COOH)2

The polymerization process involves the reaction between these two monomers, leading to the formation of the PCDT polyester polymer. The repeating unit in the polymer chain is a combination of the Polycyclohexylenedimethylene glycol and terephthalic acid units:

[-O-CH2-C6H10-CH2-O-C6H4(COOH)2-][-O-CH2-C6H10-CH2-O-C6H4(COOH)2-]

This repeating unit is connected through ester linkages, forming a long chain polymer with desirable properties such as high chemical resistance, strength, and stability.

Properties

Property Description

Specific heat capacity 0.9-1.4 J/gK

Thermal expansion coefficient 2.5-5.5 × 10-5 K-1

Thermal conductivity 0.12-0.17 W/mK

Breaking strength 40–60 cN / tex

Elongation 15-45%

Melting point 480 °C

Moisture regain 0.4-0.8%

Manufacturing Process of Polycyclohexylenedimethylene Terephthalate(PCDT PolyEster)

Polycyclohexylenedimethylene terephthalate (PCDT polyester) is a type of polyester resin known for its high heat resistance and dimensional stability. The manufacturing process of PCDT polyester involves several steps:

Raw Materials.

The primary raw materials for PCDT polyester production include:

Cyclohexanedimethanol (CHDM)

Terephthalic acid (TPA) or dimethyl terephthalate (DMT)

Catalysts and stabilizers

Polycondensation.

The synthesis of PCDT polyester begins with a polycondensation reaction between cyclohexanedimethanol and terephthalic acid (or dimethyl terephthalate). This reaction is typically carried out under high temperature and vacuum conditions to remove water as a byproduct. The result is a high-molecular-weight polymer.

Polymerization.

The polycondensation product is then subjected to a polymerization process to increase the molecular weight of the polymer chain. This step enhances the mechanical and thermal properties of the PCDT polyester.

Solidification.

The polymer is cooled and solidified to form a resin in the desired form. This can be in the form of pellets, flakes, or another suitable shape for further processing.

Melt Spinning.

In the case of PCDT polyester fibers, the solid resin is typically melted and then extruded through spinnerets to form continuous filaments. These filaments are rapidly cooled to solidify them into fibers.

Drawing and Heat Setting.

The fibers may undergo drawing, a process that aligns the molecular chains and imparts strength and orientation to the fibers. Heat setting is then performed to stabilize the structure of the fibers.

Finishing Processes.

The PCDT polyester fibers may undergo additional finishing processes such as dyeing, texturizing, or applying special coatings, depending on the intended application.

Quality Control.

Throughout the manufacturing process, strict quality control measures are implemented to ensure the final product meets the required specifications for mechanical properties, thermal stability, and other relevant characteristics.

Applications of Polycyclohexylenedimethylene Terephthalate(PCDT Polyester)

Polycyclohexylenedimethylene terephthalate (PCDT polyester) is a type of polyester that finds several applications in the textile industry due to its unique properties. Here are some key applications:

Apparel and Clothing.

PCDT polyester is commonly used in the production of apparel and clothing items. Its high durability and resistance to wrinkles make it a suitable choice for garments that require regular washing and wear.

Sportswear and Outdoor Gear.

The fabric’s strength and abrasion resistance make it suitable for sportswear and outdoor gear. It can withstand the rigors of various physical activities, providing comfort and longevity to the clothing.

Home Textiles.

PCDT polyester is employed in the manufacturing of home textiles such as beddings, curtains, and upholstery. Its resistance to fading and shrinking ensures that these products maintain their appearance and dimensions over time.

Automotive Textiles.

Due to its durability and resistance to wear and tear, PCDT polyester is used in the production of automotive textiles. This includes seat covers, headliners, and other interior fabrics, contributing to the longevity and aesthetics of vehicle interiors.

Industrial Textiles.

The robust nature of PCDT polyester makes it suitable for industrial applications. It is used in the production of various industrial textiles, including conveyor belts, filters, and other heavy-duty applications where strength and durability are crucial.

Outdoor Fabrics.

Fabrics made from PCDT polyester are well-suited for outdoor applications. They are resistant to UV radiation, making them suitable for awnings, tents, and other outdoor textiles that are exposed to sunlight.

Workwear and Uniforms.

PCDT polyester’s resistance to abrasion and its ability to maintain color and shape over time make it a popular choice for workwear and uniforms. These garments endure frequent washing and demanding working conditions without compromising on quality.

High-Performance Fabrics.

PCDT polyester is often used in the production of high-performance fabrics that require a combination of strength, flexibility, and resistance to environmental factors. This includes fabrics used in technical clothing, such as protective gear and specialized uniforms.

Textile Blends.

PCDT polyester can be blended with other fibers to enhance specific characteristics of the resulting fabric, such as moisture-wicking properties or stretch. This versatility allows manufacturers to create textiles tailored to specific applications.