MODAL FIBRE,Properties of Modal Fibre

MODAL FIBRE

1.Introduction of Modal Fibre

I believe there might be a slight error in your request. It seems like you are asking about “Modal Fiber.” Modal fiber is a type of textile made from beech tree cellulose, known for its softness, smoothness, and breathability. Here’s an introduction to Modal Fiber:

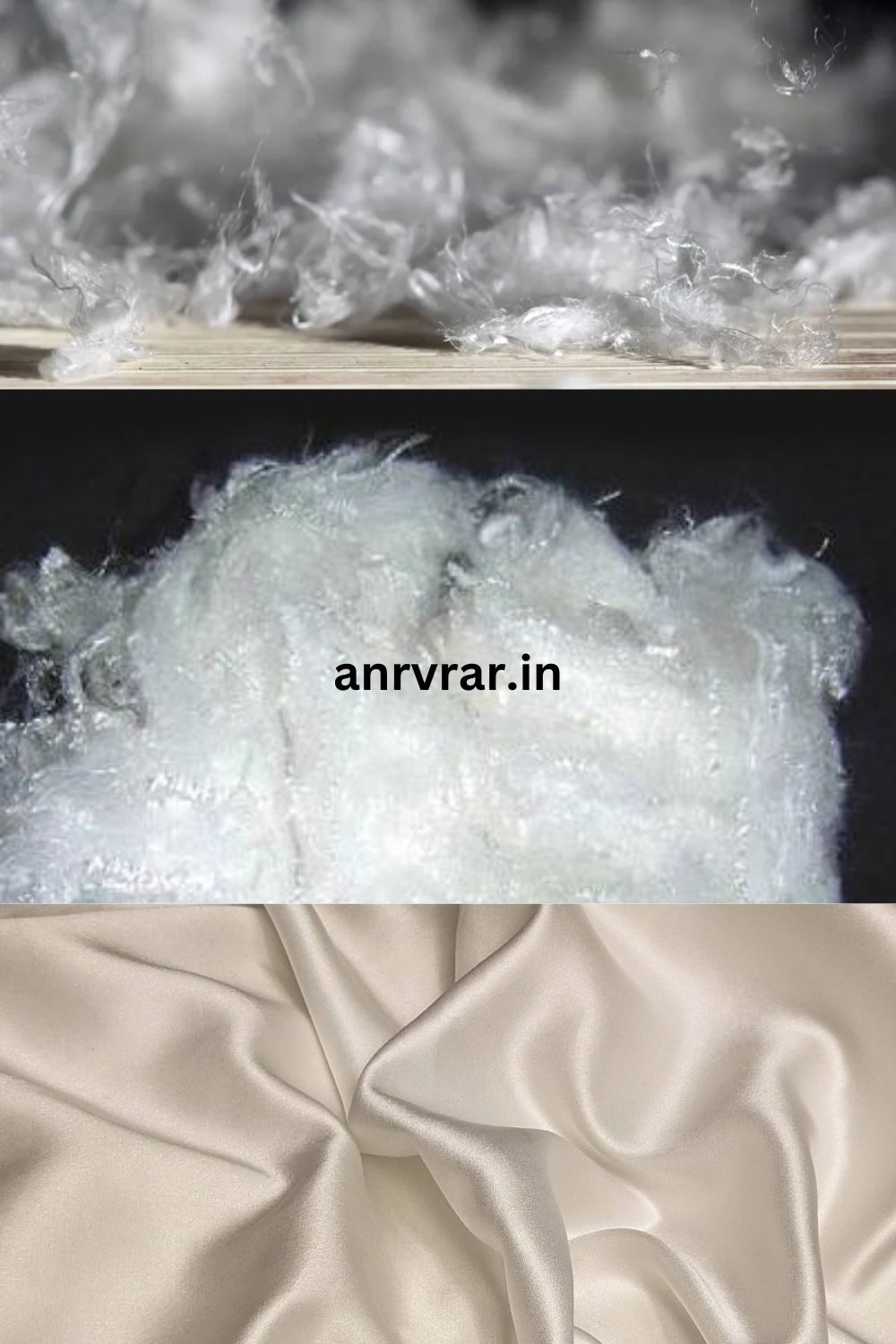

Modal fiber is a semi-synthetic cellulose fiber derived from beech trees, specifically the beechwood pulp. It falls under the category of rayon fibers, which are produced through a chemical process but with natural raw materials. Modal is known for its exceptional softness, luxurious feel, and excellent draping qualities.

The manufacturing process involves dissolving beechwood pulp into a solution, which is then extruded through spinnerets to create fine fibers. The fibers are then chemically treated and spun into yarn, resulting in a fabric that combines the comfort of natural fibers with the durability of synthetics.

One of the key features of Modal fiber is its high moisture absorption capacity, making it an excellent choice for clothing. It wicks moisture away from the body, keeping the wearer cool and dry. Additionally, Modal fabric resists wrinkling and has a smooth surface, giving it a sleek appearance and a luxurious touch.

Modal is often used in a variety of apparel, including underwear, sleepwear, activewear, and casual clothing. Its eco-friendly aspects, derived from renewable beechwood sources, contribute to its popularity in the sustainable fashion industry.

2.Properties of Modal Fibre

Here are some key properties of modal fiber:

2.1.Smooth Texture:

Modal fibers have a smooth surface, giving fabrics a silky feel. This smooth texture contributes to the overall comfort and drape of garments made from modal.

2.2.Breathability:

Modal has good moisture absorption and release properties, contributing to its breathability. This makes modal fabrics comfortable to wear in various climates as they can help regulate body temperature.

2.3.Color Retention:

Modal fibers have excellent color retention properties, allowing fabrics to maintain their vibrant colors even after multiple washes. This makes modal a popular choice for clothing items that require long-lasting color.

2.4.Strength and Durability:

While modal is softer than cotton, it still possesses good strength and durability. Modal fabrics can withstand regular wear and washing, maintaining their quality over time.

2.5.Shrink Resistance:

Modal fibers are less prone to shrinking compared to some other cellulose-based fibers. This shrink resistance contributes to the longevity of garments made from modal.

2.6.Environmental Sustainability:

Modal is considered a more environmentally sustainable option compared to some other synthetic fibers. The production process involves using beech trees, which are a renewable resource. Additionally, the closed-loop manufacturing process used for modal production minimizes environmental impact.

2.7.Biodegradability:

Modal fibers are biodegradable, meaning they can naturally break down over time, reducing their environmental impact compared to some synthetic fibers.

2.8.Anti-Bacterial Properties:

Modal fibers have been reported to have some natural anti-bacterial properties, which can contribute to keeping fabrics fresher for longer periods between washes.

3.Chemical Properties of Modal Fibre.

Here are some of the chemical properties of modal fiber:

3.1.Composition:

Modal is composed of cellulose, a natural polymer found in plant cell walls. The cellulose used in modal is extracted from beech wood through a chemical process.

3.2.Chemical Structure:

Modal has a similar chemical structure to other cellulose fibers. It consists of glucose units linked together by β-1,4-glycosidic bonds. The repeating unit in the polymer chain is cellobiose.

3.4.Reactivity:

Modal is known for its high reactivity to chemical treatments. This makes it easier to dye compared to some other cellulose fibers, and it can be blended with other fibers for various applications.

3.5.Hydrophilic Nature:

Like other cellulose fibers, modal is hydrophilic, meaning it has a strong affinity for water. This property contributes to its breathability and moisture absorption, making it comfortable to wear.

3.6.Tenacity and Strength:

Modal fibers exhibit good strength and tenacity, providing durability to the fabric. The strength is influenced by the degree of polymerization and processing conditions.

3.7.Softness:

Modal is known for its soft and smooth feel, which is a result of the fine fibers produced during the manufacturing process. The softness makes it comfortable for clothing applications.

3.8.Color Retention:

Modal fibers have good color retention properties, and the fabric maintains its color well after dyeing. This makes modal garments resistant to fading.

3.9.Thermal Stability:

Modal fibers have good thermal stability, allowing them to withstand various temperature conditions without significant degradation. This property contributes to the durability of modal fabrics.

TABLE.1

Specific Gravity(g/cc) 1.53

Tenacity

WET 2.2 TO 4.0

DRY 3.8 TO 5.0

Moisture Regain(%) 11.8 %

Elongation(%)

WET 7.0 %

DRY 8.5%

Dimensional Stability Good

4.Manufacturing Process of Modal Fibre.

Modal fiber is a type of semi-synthetic cellulose fiber made by spinning reconstituted cellulose, typically from beech tree pulp. The manufacturing process of Modal fiber involves several steps:

4.1.Harvesting and Pulping:

Beech trees are typically used for Modal fiber production. The wood is harvested, and the bark is removed.

The wood chips are then subjected to a chemical pulping process, where they are broken down into cellulose fibers through a combination of chemicals and mechanical processes.

4.2.Cellulose Extraction:

The cellulose is extracted from the pulped wood using a chemical process, usually involving sodium hydroxide and carbon disulfide. This creates a viscose solution, similar to the process used for viscose rayon.

4.3.Filament Formation:

The viscose solution is then forced through spinnerets (tiny holes) to create fine filaments.

These filaments are then solidified through a coagulation bath, which typically contains a solution of sulfuric acid and sodium sulfate.

4.4.Washing and Neutralization:

The newly formed fibers go through a series of washing steps to remove any residual chemicals.

The fibers are then neutralized to ensure they are not acidic, usually with an alkaline solution.

4.5.Drawing and Spinning:

The fibers may undergo drawing, a stretching process that aligns the molecules and improves the fiber’s strength and elasticity.

The drawn fibers are then spun into yarn.

4.6.Finishing:

The yarn or fibers may undergo additional finishing processes to enhance their properties, such as softness, color, or moisture absorption.

4.7.Drying and Cutting:

The fibers or yarn are dried to remove any remaining moisture.

They may be cut into desired lengths, depending on the intended application.

5.Advantages of Modal Fibre

I believe you may be referring to “Modal” fiber, which is a type of textile fiber derived from beech trees. Modal is a semi-synthetic fiber, and its advantages include:

5.1.Softness.

Modal fibers are known for their exceptional softness, often described as being as soft as silk. This makes modal fabric comfortable to wear against the skin.

5.2.Breathability.

Modal has good breathability, allowing moisture to be easily absorbed and released. This feature makes modal garments suitable for warm weather and activities that may cause sweating.

5.3.Color Retention.

Modal fibers have excellent color retention properties, meaning that the fabric retains its color well over time, even after multiple washes.

5.4.Durability.

Modal is relatively strong and durable, which contributes to the longevity of garments made from this fiber.

5.5.Smooth Texture.

Modal fabrics have a smooth and silky texture, providing a luxurious feel. This makes them a popular choice for intimate apparel, sleepwear, and casual wear.

5.6.Environmentally Friendly.

Modal is often considered more environmentally friendly than some other fibers. It is derived from beech trees, which are a renewable resource. The production process also uses less water compared to cotton.

5.7.Biodegradability.

Modal is biodegradable, meaning it can naturally break down over time, reducing its environmental impact.

5.8.Shrink Resistance.

Modal fabrics are less prone to shrinking compared to some other natural fibers, contributing to the garment’s ability to maintain its shape after washing.

6.Disadvantage of Modal Fibre

It also has some disadvantages.

6.1.Durability.

Modal fibers may not be as durable as some other synthetic fibers, such as polyester. This can result in a shorter lifespan for garments made from Modal, especially if they are subjected to frequent washing and wear.

6.2.Wrinkling.

Modal fibers can be more prone to wrinkling compared to some other fibers. This may require more care in terms of ironing or steaming to maintain a smooth appearance, particularly in clothing items.

6.3.Environmental Impact.

While Modal is often considered a more eco-friendly option compared to traditional rayon or other synthetic fibers, the production process still involves the use of chemicals and energy. Additionally, the environmental impact depends on the specific manufacturing practices of the company producing the Modal fiber.

6.4.Limited Heat Resistance.

Modal fibers have a lower heat resistance compared to some synthetic fibers. This means that garments made from Modal may not be as suitable for high-temperature ironing or other applications that involve exposure to heat.

https://sewport.com/fabrics-directory/modal-fabric