Isotropic Pitch-Based Carbon Fibers

Isotropic Pitch-Based Carbon Fibers

Introduction

Isotropic pitch-based carbon fibers have emerged as a game-changer in the realm of advanced materials, captivating the attention of scientists, engineers, and industry enthusiasts alike. In this exploration, we’ll unravel the mysteries surrounding these exceptional fibers, from their unique properties to groundbreaking applications.Isotropic pitch-based carbon fibers find their origin in specialized carbonization processes involving pitch—a viscoelastic material derived from coal tar or petroleum. The result is a material with remarkable isotropic properties, meaning its physical characteristics exhibit uniformity in all directions. This intrinsic quality sets these carbon fibers apart, paving the way for diverse applications across industries.

Composition and Manufacturing Process

The Core Essence

Isotropic Pitch-Based Carbon Fibers derive their exceptional properties from a well-calibrated composition. The core essence lies in the isotropic pitch, a high-quality precursor that sets the stage for unparalleled strength and versatility.

Bonds Beyond Ordinary

One of the defining characteristics is the molecular arrangement, creating bonds that transcend the ordinary. These fibers boast a unique structure, paving the way for remarkable thermal and mechanical properties.

Precision in Processing

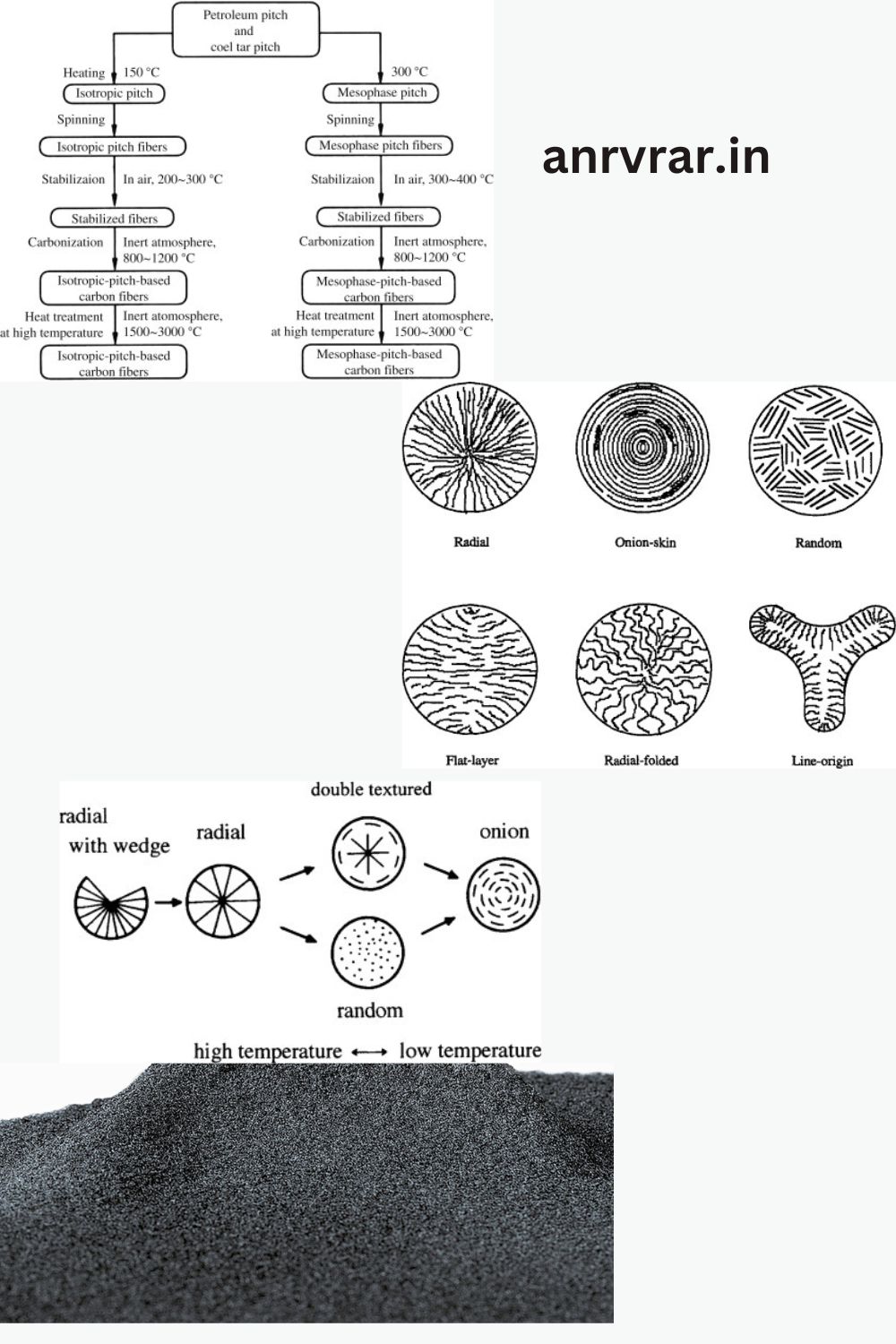

The journey from pitch to fiber involves a series of precision-driven steps. The manufacturing process begins with meticulous pitch stabilization, ensuring the precursor’s structural integrity. This stage lays the foundation for the subsequent transformative phases.

Spinning Wonders

Spinning, a pivotal phase in the process, orchestrates the conversion of stabilized pitch into fibers. The controlled conditions during spinning dictate the ultimate strength and uniformity of the resultant carbon fibers.

Heat, the Alchemist’s Touch

Heat treatment becomes the alchemist’s touch, as the fibers undergo controlled pyrolysis. This crucial step imparts the desired carbon content, culminating in fibers that defy conventional limitations.

Aerospace Marvels

The aerospace industry finds a reliable ally in these fibers, where lightweight yet robust materials are imperative. Isotropic Pitch-Based Carbon Fibers contribute to the creation of high-performance components, elevating aerospace technologies.

Automotive Evolution

In the realm of automotive engineering, these fibers find applications in crafting lightweight, fuel-efficient vehicles. The balance of strength and weight opens avenues for groundbreaking designs and enhanced fuel efficiency.

Eco-Friendly Footprint

Beyond their mechanical prowess, Isotropic Pitch-Based Carbon Fibers contribute to sustainability efforts. Their production processes, when compared to traditional materials, often result in a lower environmental footprint. This eco-friendly aspect aligns seamlessly with the growing global focus on sustainable practices.

Recycling Realities

In an era where environmental responsibility is paramount, the recyclability of these carbon fibers adds a significant layer of appeal. The ability to repurpose and recycle them further reduces waste, aligning with circular economy principles.

Continuous Innovation

The journey doesn’t end with current applications; ongoing research pushes the boundaries of what Isotropic Pitch-Based Carbon Fibers can achieve. Scientists and engineers continually explore new avenues, unveiling possibilities that could revolutionize industries yet to be touched by this extraordinary material.

Integration Challenges

While the potential is vast, challenges persist in integrating these fibers into certain applications. Overcoming obstacles related to cost and scalability remains a focal point for researchers aiming to broaden the scope of Isotropic Pitch-Based Carbon Fiber applications.

Informed Decisions

As consumers, understanding the impact of Isotropic Pitch-Based Carbon Fibers on products is crucial. With awareness comes the power to make informed choices, supporting industries that prioritize technological advancement and environmental responsibility.

Collaborative Ventures

The road ahead involves collaborative ventures between industries and researchers. By fostering partnerships, we can accelerate the integration of Isotropic Pitch-Based Carbon Fibers into mainstream applications, bringing about a paradigm shift in various sectors.

Global Adoption

The global adoption of these fibers hinges on disseminating knowledge and demystifying their complexities. As industries worldwide grasp the benefits, we can anticipate a widespread embrace of Isotropic Pitch-Based Carbon Fibers in diverse applications.

Properties of Isotropic Pitch-Based Carbon Fibers

High Tensile Strength

At the core of Isotropic Pitch-Based Carbon Fibers lies unparalleled tensile strength. These fibers boast remarkable resistance to pulling forces, making them ideal for applications where durability is paramount.

Thermal Stability

One of the standout qualities of these carbon fibers is their impressive thermal stability. They can endure high temperatures without compromising their structural integrity, making them invaluable in environments with extreme heat conditions.

Lightweight Marvels

Isotropic Pitch-Based Carbon Fibers redefine the concept of strength-to-weight ratio. Despite their robust nature, these fibers are remarkably lightweight, making them a preferred choice in aerospace and automotive industries, contributing to fuel efficiency and enhanced performance.

Electrically Conductive

In the ever-evolving landscape of technology, these carbon fibers shine as they possess excellent electrical conductivity. This unique property opens avenues for their application in electronic components, ensuring optimal performance.

Automotive Industry Revolution

Isotropic Pitch-Based Carbon Fibers play a pivotal role in revolutionizing the automotive sector. From lightweight body panels to components enhancing fuel efficiency, these fibers are driving innovation on the road.

Aerospace Advancements

In the aerospace domain, these carbon fibers soar to new heights. Their combination of strength and low weight makes them an ideal choice for aircraft components, contributing to enhanced fuel efficiency and overall performance.

Electronic Marvels

The electrical conductivity of Isotropic Pitch-Based Carbon Fibers makes them indispensable in the creation of cutting-edge electronic devices. From circuit boards to high-performance gadgets, these fibers play a crucial role in powering our tech-driven world.

Advantages over traditional materials of Isotropic Pitch-Based Carbon Fibers

The Power of Strength

Isotropic Pitch-Based Carbon Fibers redefine durability. With a strength that surpasses traditional materials, these fibers boast robustness and resilience, making them the go-to choice for industries requiring high-performance materials.

Lightweight

One of the standout advantages lies in the exceptional lightweight nature of Isotropic Pitch-Based Carbon Fibers. Unlike traditional materials that add bulk, these fibers provide strength without compromising on weight. A boon for aerospace and automotive applications seeking optimal performance.

Thermal Prowess

Isotropic Pitch-Based Carbon Fibers shine in their ability to withstand extreme temperatures. This thermal resistance makes them ideal for applications in industries where exposure to high heat is a constant challenge. From aerospace engineering to energy production, these fibers outshine traditional materials with their impressive heat tolerance.

Electric Conductivity

In the ever-evolving landscape of technology, Isotropic Pitch-Based Carbon Fibers bring forth a remarkable advantage – superior electric conductivity. This characteristic makes them a prime choice for electronic components, ensuring enhanced performance and efficiency compared to their traditional counterparts.

Corrosion Resistance

Say goodbye to the woes of corrosion. Isotropic Pitch-Based Carbon Fibers offer exceptional resistance to corrosive elements, ensuring longevity and reliability in diverse applications. Industries requiring materials that can withstand harsh environmental conditions find a trustworthy ally in these advanced carbon fibers.

Environmental Friendliness

Embracing Isotropic Pitch-Based Carbon Fibers isn’t just a leap in performance but also a step towards sustainability. Compared to traditional materials, these fibers present an eco-friendly alternative, aligning with the global push for greener practices in manufacturing and production.

Disadvantages of Isotropic Pitch-Based Carbon Fibers

Limited Mechanical Strength

One of the prominent drawbacks of isotropic pitch-based carbon fibers lies in their limited mechanical strength. While they boast impressive tensile strength, their overall mechanical performance falls short when compared to alternative materials. Engineers and manufacturers must carefully weigh this aspect when considering applications with high mechanical stress.

Vulnerability to Environmental Factors

Unlike some of their counterparts, isotropic pitch-based carbon fibers are susceptible to environmental factors. Exposure to harsh weather conditions, extreme temperatures, or corrosive substances can compromise their structural integrity over time. This vulnerability poses a significant challenge in applications where durability is paramount.

Challenging Manufacturing Process

The production of isotropic pitch-based carbon fibers involves a complex and meticulous manufacturing process. This complexity not only increases production costs but also presents challenges in scaling up manufacturing operations. Companies need to invest substantially in advanced technology and skilled labor to overcome these hurdles.

Cost Implications

While the unique properties of isotropic pitch-based carbon fibers make them desirable for certain applications, the cost factor cannot be overlooked. The production costs associated with these fibers are relatively high, impacting the overall cost-effectiveness of end products. This cost consideration may influence industries with budget constraints to explore alternative materials.

Limited Design Flexibility

Despite their impressive characteristics, isotropic pitch-based carbon fibers come with limitations in design flexibility. The structural orientation during the manufacturing process restricts the range of shapes and forms that can be achieved. This limitation may be a decisive factor in industries where intricate and diverse designs are essential.

Recycling Challenges

The environmental impact of materials is a growing concern, and isotropic pitch-based carbon fibers pose challenges in this regard. The recycling process for these fibers is intricate and not as straightforward as with some other materials. This raises questions about their long-term sustainability and eco-friendliness.

Limitations of Isotropic Pitch-Based Carbon Fibers

Enhancing Structural Integrity

By incorporating steric support in the production process, the structural integrity of Isotropic Pitch-Based Carbon Fibers reaches unprecedented levels. This enhancement not only addresses previous vulnerabilities but opens doors to applications that demand superior strength.

Elevating Thermal Performance

Steric support contributes significantly to improving the thermal conductivity of these carbon fibers. This means more efficient heat dissipation, making them ideal for high-temperature environments. Industries relying on thermal stability now have a reliable ally.

Redefining Flexibility

One of the notable limitations of conventional carbon fibers is their brittleness. Steric support mitigates this issue, introducing a newfound flexibility without compromising strength. This breakthrough widens the scope of applications, especially in dynamic and demanding scenarios.

Precision in Production

Steric support introduces a level of precision previously unseen in the manufacturing of Isotropic Pitch-Based Carbon Fibers. This ensures consistency in fiber quality, addressing concerns related to variations that may have hindered widespread adoption.

Streamlining Production Costs

The integration of steric support not only enhances the quality of carbon fibers but also streamlines the production process, leading to cost efficiencies. This is a crucial factor in making these advanced materials more accessible across diverse industries.

Aerospace

In the aerospace industry, where weight and strength are paramount, the enhanced structural integrity of Isotropic Pitch-Based Carbon Fibers with steric support proves invaluable. The lightweight yet robust nature opens avenues for the development of more fuel-efficient and agile aircraft.

Automotive

Steric-supported carbon fibers are making waves in the automotive sector. From reinforcing chassis for improved safety to contributing to the development of electric vehicles through enhanced thermal performance, these fibers are driving innovations at every turn.

Renewable Energy

The renewable energy sector benefits significantly from the thermal conductivity of Isotropic Pitch-Based Carbon Fibers with steric support. This translates to more efficient heat transfer in solar panels and improved durability in wind turbine components, propelling the green energy revolution forward.

Defects of Isotropic Pitch-Based Carbon Fibers

Inhomogeneity

Isotropic pitch-based carbon fibers may exhibit variations in composition and structure throughout their length. Inhomogeneity can lead to inconsistent mechanical and thermal properties, impacting the overall performance of the material.

Void Formation

During the carbonization process, voids or gaps may form within the structure of the carbon fibers. These voids can compromise the mechanical strength and stiffness of the material, reducing its overall structural integrity.

Impurities

Impurities in the pitch precursor or introduced during the manufacturing process can result in the formation of non-carbonaceous components within the fibers. These impurities can weaken the carbon-carbon bonds and contribute to lower thermal and mechanical properties.

Anisotropy

Despite being called isotropic pitch-based carbon fibers, some level of anisotropy (directional dependence of properties) may still be present. Anisotropy can affect the predictability and uniformity of the material’s behavior under different loading conditions.

Surface Irregularities

The surface of carbon fibers may have irregularities, such as cracks or roughness, which can weaken the fiber and affect its adhesion properties when used as a reinforcement in composite materials.

Sensitivity to Processing Conditions

The properties of isotropic pitch-based carbon fibers are highly dependent on the processing conditions during manufacturing. Variations in temperature, pressure, and other parameters can lead to inconsistencies in fiber properties.

Low Oxidation Resistance

Isotropic pitch-based carbon fibers may have limited resistance to oxidation at elevated temperatures. This can result in a reduction of their mechanical properties when exposed to oxidative environments.

Cost and Production Challenges

The production of high-quality isotropic pitch-based carbon fibers can be expensive and may involve complex processing techniques. The cost of production and the challenges associated with achieving consistent quality can be limitations for widespread industrial use.

https://www.sciencedirect.com/topics/engineering/pitch-based-carbon-fiber

FAQs:

Are isotropic pitch-based carbon fibers environmentally friendly?

Yes, these fibers are environmentally friendly, with recycling possibilities and a reduced carbon footprint.

How do isotropic pitch-based carbon fibers compare to other carbon fibers?

They stand out for their balanced combination of strength, conductivity, and lightweight characteristics.

What challenges are associated with the production of isotropic pitch-based carbon fibers?

Challenges include refining manufacturing processes to enhance efficiency and address specific application requirements.

Can isotropic pitch-based carbon fibers be used in medical implants?

Yes, their biocompatibility makes them suitable for use in various medical applications, including implants.