Mastering Fiberglass Hand Layup Techniques

Hand Layup Techniques

Introduction

Hand lay-up Method is the simplest method of composite processing. The infrastructural requirement for this method is also minimal. The processing steps are quite simple.

First of all, a release gel is sprayed on the mold surface to avoid the sticking of polymer to the surface.

Reinforcement in the form of woven mats or chopped strand mats are cut as per the mold size and placed at the surface of mold after.

Then thermosetting polymer in liquid form is mixed thoroughly in suitable proportion with a prescribed hardner (curing agent) and poured onto the surface of mat already placed in the mold.

The polymer is uniformly spread with the help of brush and roller. Second layer of mat is then placed on the polymer surface and a roller is moved with a mild pressure on the mat-polymer layer to remove any air trapped as well as the excess polymer present.

The method is repeated for each layer of polymer and mat, till the required layers are stacked.

After curing either at room temperature or at some specific temperature, mold is opened and the developed composite part is taken out and further processed.

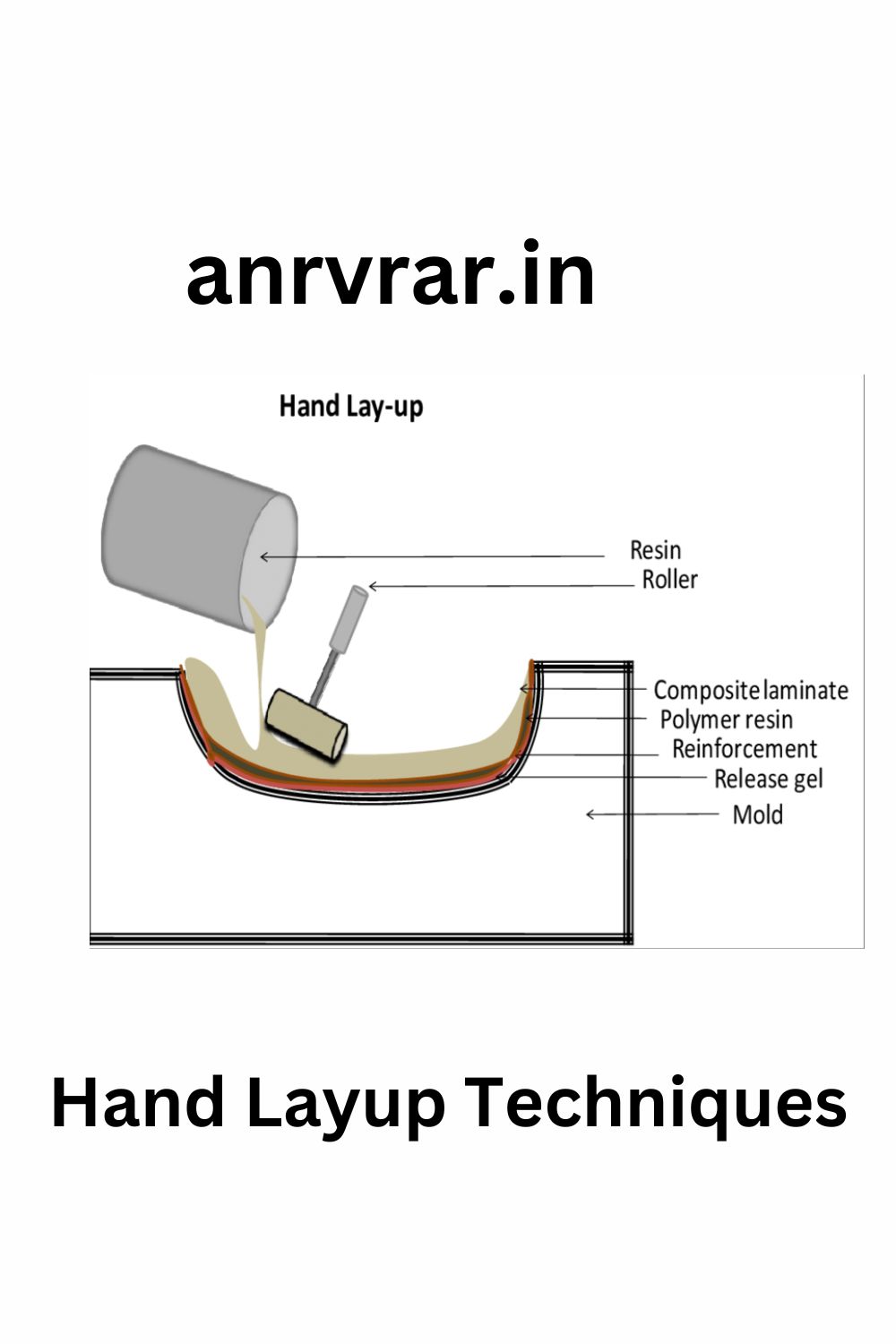

The schematic of hand lay-up is shown below:

Capital and infrastructural reqirement is less as compared to other methods. Production rate is less and high volume fraction of reinforcement is difficult to achieve in the processed compositeshttps://anrvrar.in/?p=12.

The advantages of the FRP Hand lay-up Method

1) Complicated equipment is not required, it just needs simple mould and tools, so less investment, quick effect, and It’s suitable for the development of township.

2) Production technology is easy to master, after a short training, it can be mastered, but it will take a long time experience and study to achieve extremely good product

3) The production of FRP are not limited by size and shape, such as: large cruise ships, round roof, sink, etc.;

4) It can be joint with other materials (such as: metal, wood, foam, etc.) at the same time;

5) For some of the large products (such as: large can, large roof) can be produced on the spot.

6) It is suitable for the production of large-sized, small-volume, complex-shaped products, simple equipment, low investment, quick effect,

7) Simple, the production technology is easy to master, and it can be produced only after short-term training

8) It is easy to meet the design needs of the product.

9) It can be arbitrarily added to The reinforcing materials in different parts of the product.

10) The resin content of the product is high and the corrosion resistance is good.

Hand Lay-up Method

FRP hand layup method disadvantages:

1) Product quality is not as stable machine. Because of the difference of the level of operating personnel and the production of environmental conditions, the stability of product quality is not very good;

2) There is powder and smells in production environment. Therefore, hand lay up molding process has its advantages and can’t be replaced by other methods, the existing shortcomings should be overcome in operation process.

3) Long production cycle.

4) Not suitable for mass production.

5) The product quality is not easy to control.

6) Performance stability is not high.

7) Product mechanical properties are low.

8) Production environment is poor.

9) Odor is Dust is much during processing.

Protection molding method classification:

https://anrvrar.in/wp-admin/post.php?post=44&action=edit

Hand paste molding is divided into wet method and dry method: The wet method is to directly enhance the reinforcing material (cloth, belt, felt) with or without solvent glue, and its impregnation and preforming process At the same time, the specific process of wet hand lay-up is: first apply a layer of release agent on the mold, then evenly apply a layer of resin mixture added with curing agent.

And then fiber-reinforced fabric (according to the required shape and size Cut directly on the glue layer, use a scraper, brush or pressure roller to force the resin glue to evenly immerse into the fabric, and eliminate the bubbles. The material to be reinforced is completely pasted by the resin glue, and then cured and demolded. ,Trimming. About 50% of FRP products are currently manufactured using a wet hand lay-up process.

Dry hand lay-up is to pre-form the prepreg according to the layering sequence, separate the impregnation and pre-forming process, obtain the preform blank, and then solidify the molding by molding or vacuum bag-heating can.

Dry hand lay-up is: using prepreg as raw material, first cutting the prepreg (cloth) into blank according to the sample, heating and softening when layering, and then adhering to the mold layer by layer And pay attention to the exclusion of interlayer Bubbles, so that the compaction, this method is more often used in autoclave and bag compression molding.

Defects and solutions in hand lay-up method:

- Bubble: When pasting the mold, often due to too much resin. the content of bubbles in the glue is too much,he viscosity of the resin glue is too large, the material of Zengqing is not properly selected.the glass cloth The layer is not pressed tightly, etc., causing a large number of bubbles on the surface of the mold and the cavity, which seriously affects the quality and surface roughness of the mold. At present, the amount of glue is controlled, the resin glue is vacuum defoamed, and an appropriate amount of diluent is added. (such as acetone), choose to use a glass cloth that is easy to saturate the resin, etc. to reduce the generation of bubbles.

- 2.Flowing glue: When the mold is manually pasted, the phenomenon of glue flowing often occurs. The main reasons for the flow of glue are: a. The viscosity of the resin is too low, B; the ingredients are not uniform, and the amount of curing agent is less. The filler increases the viscosity of the resin (such as silica), and appropriately adjusts the amount of the curing agent to avoid the occurrence of flow.

3.Layering: Due to the insufficient amount of resin and the lack of tightness of the glass cloth layer, the heating temperature of the premature heating product is too high, etc., which will cause the mold to stratify. Therefore, in the paste, it It is necessary to control enough glue, try to The laminate is laminated, and the resin is not heated as much as possible before the gel, and the heating temperature is appropriately controlled.

4.Cracks: When making and using molds, we often see cracks on the surface of the mold. The main reason for this phenomenon is that the gel coat layer is too thick and affected by uneven hair removal. The thickness of the mold gel coat should be Strictly controlled. When demoulding, the mold should be punched with a hard object, preferably with compressed air.

Please tell me more about your excellent articles

Thank you for your post. I really enjoyed reading it, especially because it addressed my issue. It helped me a lot and I hope it will also help others.

thankyou

Thank you so much for giving everyone an extraordinarily marvellous chance to read from this blog. It really is so pleasing and as well , packed with fun for me and my office fellow workers to visit your web site not less than 3 times a week to read through the fresh tips you have got. And of course, I’m just certainly astounded considering the awesome thoughts served by you. Some 2 ideas on this page are in fact the finest we have had.

It’s appropriate time to make some plans for the future and it is time to be happy. I’ve read this post and if I could I want to recommend you few interesting things or suggestions. Perhaps you could write subsequent articles referring to this article. I desire to read more things approximately it!