Glass Fibre,Applications of Glass Fibre

Glass Fibre

Introduction

Glass fiber, also known as fiberglass, is a remarkable material that has found its way into various industries due to its exceptional properties and versatility. From telecommunications to construction, automotive to aerospace, glass fiber has made its presence felt in countless applications. In this article, we will explore the intricacies of glass fiber, shedding light on its origins, manufacturing methods, types, applications, advantages, and what the future holds for this incredible material,glass fiber plays a pivotal role in shaping the modern world.

1.Exceptional Strength

One of the standout features of glass fibre is its exceptional strength-to-weight ratio. This property makes it a preferred choice for reinforcing materials in construction, such as concrete and plastics. Structures fortified with glass fibre are not only lighter but also remarkably durable.

2. Corrosion Resistance

Glass fibre is highly resistant to corrosion, a crucial factor in the construction of structures exposed to harsh environments. This resistance ensures that buildings and components made with glass fibre have a longer lifespan, reducing maintenance costs.

3. Thermal Insulation

Another remarkable property of glass fibre is its thermal insulation capabilities. It effectively traps air, creating an insulating layer that helps regulate temperature. This feature makes it ideal for applications in the automotive and HVAC industries.

4. Electrical Insulation

Glass fibre electrical insulation properties are also highly valued. It is used in the production of circuit boards and electrical components, where it ensures the safe and efficient transmission of electricity.

Fiber Optics

In the realm of telecommunications and data transmission, the role of glass fiber is nothing short of revolutionary. The optical properties of glass fiber enable the transmission of data at speeds that were once considered inconceivable. The intricate dance of photons within the glass strands forms the backbone of our interconnected world, facilitating global communication with astonishing efficiency.

Glass Fiber in Quantum Computing

In the cutting-edge realm of quantum computing, glass fiber plays a pivotal role in the realization of quantum networks. Its ability to transmit quantum information with minimal losses is a testament to its unique properties. The perplexing world of quantum entanglement finds a reliable conduit in the intricate strands of glass fiber, propelling humanity toward a new era of computation.

Manufacturing Glass Fiber

To understand glass fiber, it’s essential to comprehend how it’s made. This chapter will provide an in-depth look at the manufacturing process, including:

Raw materials: silica, alumina, and others.Melting the glass.Formation of glass filaments.Applying sizing and coatings.Winding and forming into different products

Properties of Glass Fiber

Glass fiber isn’t a one-size-fits-all material; there are various types with unique properties tailored for specific applications. This chapter will discuss:

Mechanical properties,Thermal properties,Electrical properties,Chemical resistance,Comparisons with other materials

Environmental Impact and Sustainability

With growing concerns about sustainability, it’s crucial to assess the environmental impact of glass fiber production and use. This chapter will discuss:

Energy consumption in manufacturing. Recycling and waste management. Life cycle assessments. Sustainable alternatives and innovations.

Manufacturing Process

The production of glass fiber is a fascinating process that involves the conversion of raw materials like silica sand, limestone, and alumina into thin, flexible fibers. This is achieved through a multi-step process that includes melting, extrusion, and cooling. The result is a material with exceptional tensile strength and durability, making it suitable for a wide range of applications.

Applications

The versatility of glass fiber is evident in its wide range of applications. From reinforcing concrete structures to manufacturing lightweight composites for aircraft, glass fiber has become an integral part of modern industries. It is also extensively used in telecommunications for transmitting high-speed data over long distances.

Challenges and Limitations

While glass fiber offers numerous benefits, it is not without its challenges. One of the primary concerns is its brittleness, which can lead to issues in certain applications. Moreover, the production of glass fiber requires substantial energy, contributing to its carbon footprint.

Evolution of Glass Fiber Technology

Over the decades, advancements in glass composition, manufacturing processes, and equipment led to significant breakthroughs in the glass fiber industry. By the mid-20th century, glass fiber had emerged as a material with incredible potential and diverse applications.

The Glass Fiber Manufacturing Process

Raw Materials: Sand, Silica, and More

The journey of glass fiber begins with basic raw materials such as sand, silica, limestone, and alumina. These ingredients are carefully selected to create the ideal glass composition.

The Melting Process

The raw materials are melted at high temperatures in a furnace, resulting in a molten glass state. This molten glass is then carefully manipulated into fibers using various techniques.

Fiber Formation Techniques

Glass fibers can be produced using several methods, including centrifugal spinning, drawing, and extrusion. Each technique has its advantages and is chosen based on the desired properties of the final product.

Sizing and Coating

To improve adhesion and performance, glass fibers are coated with a sizing material. This coating plays a crucial role in ensuring the fibers bond effectively with other materials in composite applications.

Quality Control and Inspection

Stringent quality control measures are in place to monitor the diameter, strength, and other essential characteristics of the glass fibers. This ensures that the end product meets the required specifications.

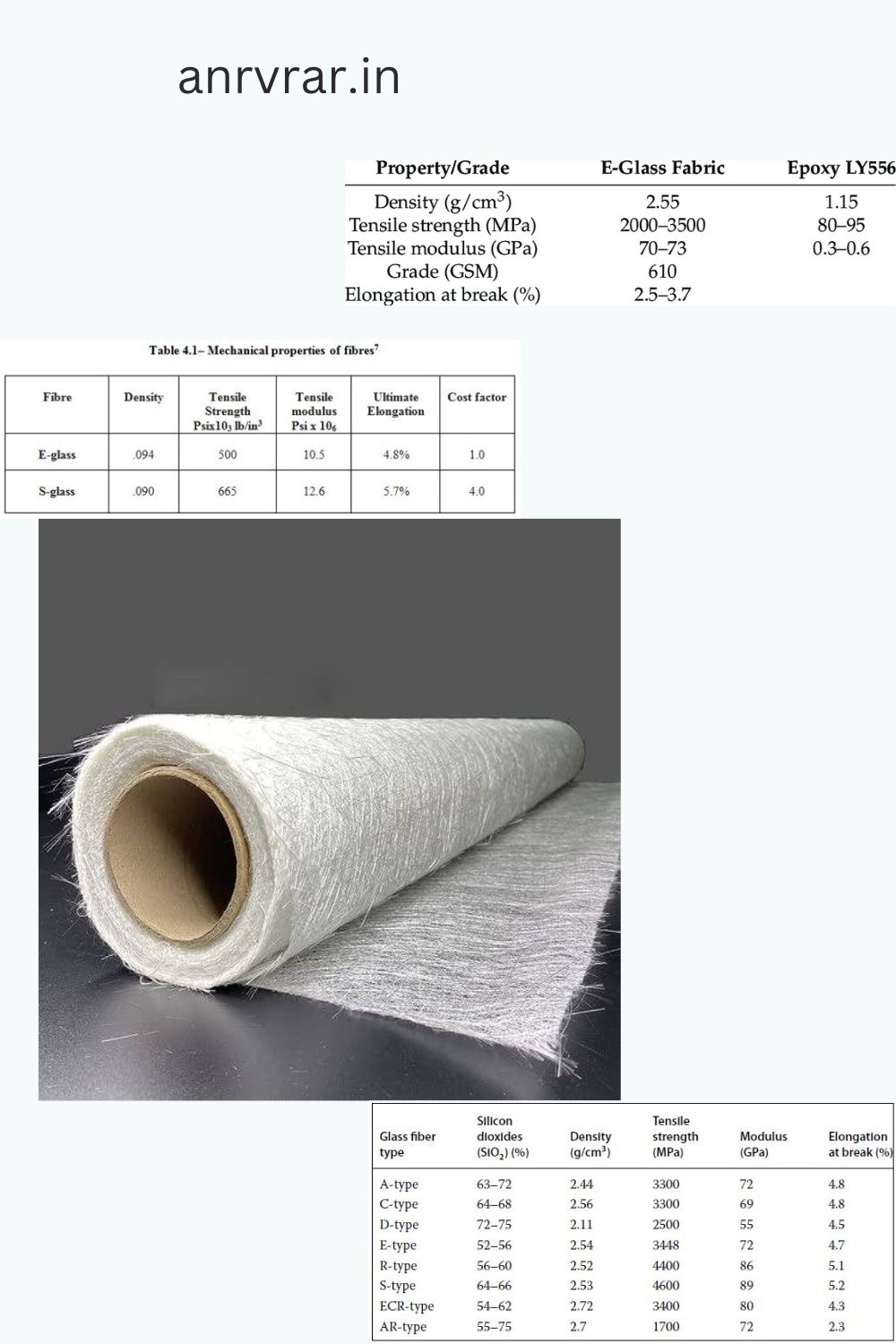

Types of Glass Fiber

E-Glass: The Most Common Variant

E-Glass, or electrical glass, is the most widely used type of glass fiber. It offers excellent electrical insulation properties and is commonly found in electronic and telecommunication applications.

S-Glass: For Superior Strength

S-Glass, or structural glass, is known for its exceptional strength. It finds extensive use in applications where high tensile strength is a requirement, such as aerospace and military equipment.

C-Glass: Chemical Resistance

C-Glass, or chemical-resistant glass, is designed to withstand harsh chemical environments. It is often used in industrial settings where resistance to corrosion is essential.

A-Glass: The Alkali-Resistant Choice

A-Glass, or alkali-resistant glass, is primarily used in cement reinforcement applications. It provides excellent resistance to alkali attack, making it suitable for construction purposes.

Properties and Advantages

High Strength-to-Weight Ratio

One of the standout features of glass fiber is its impressive strength-to-weight ratio. It is stronger than steel on a per-weight basis, making it a preferred choice in applications where weight reduction is critical.

Excellent Thermal Insulation

Glass fiber offers exceptional thermal insulation properties, making it invaluable in construction and manufacturing processes where temperature control is essential.

Corrosion Resistance

Glass fiber is inherently corrosion-resistant, ensuring longevity in harsh environments and reducing maintenance costs.

Electrical Insulation

In electronic and telecommunication applications, the electrical insulation properties of glass fiber play a vital role in ensuring signal integrity and safety.

Lightweight and Durable

Despite its strength, glass fiber is remarkably lightweight, making it an ideal choice for applications where weight reduction is a priority.

Applications Across Industries

Construction and Architecture

Glass fiber reinforced concrete (GFRC) is increasingly used in architectural designs due to its durability and flexibility.

Aerospace and Aviation

Glass fiber composites are used in aircraft components, reducing weight and enhancing fuel efficiency.

Automotive Advancements

Automakers incorporate glass fiber components to improve vehicle safety and fuel economy.

Telecommunications

Glass fiber optic cables enable high-speed data transmission over long distances.

Sustainable Manufacturing Practices

Manufacturers are adopting eco-friendly processes to minimize the environmental footprint of glass fiber production.

Life Cycle Analysis

A comprehensive assessment of the environmental impact of glass fiber helps identify areas for improvement and sustainability initiatives.

Future Innovations in Glass Fiber

Nanotechnology Integration

Nanomaterials are being integrated into glass fiber to enhance its properties and open up new possibilities.

Smart Materials and IoT

Glass fiber is at the forefront of the Internet of Things (IoT) revolution, enabling the development of smart, connected devices.

Advancements in Composite Materials

Ongoing research is focused on developing advanced composite materials that leverage the unique properties of glass fiber.

Eco-Friendly Solutions

The industry is actively exploring sustainable alternatives and processes to reduce its environmental impact.

Health and Safety Concerns

Environmental Concerns

While glass fiber is recyclable, the industry is working to address environmental concerns associated with its production.

The Endless Potential of Glass Fiber

As we conclude this journey through the world of glass fiber, it’s clear that its potential is boundless. This versatile material has reshaped industries and continues to evolve with innovations in technology and sustainability.https://en.wikipedia.org/wiki/Glass_fiber

FAQs (Frequently Asked Questions)

1.Is glass fiber stronger than steel?

Glass fiber is stronger than steel on a per-weight basis, making it an excellent choice for applications where weight reduction is critical.

2.Are there any health risks associated with working with glass fiber?

Occupational exposure to glass fiber particles may pose health risks, so it’s essential to follow proper safety precautions when handling it.

3.Can glass fiber be recycled?

Yes, efforts are underway to recycle glass fibers, reducing waste and promoting sustainability.

4.What are the primary advantages of using glass fiber in construction?

Glass fiber reinforced concrete (GFRC) is increasingly used in architectural designs due to its durability and flexibility.

What is Glass Fibre?

Glass fibre, often referred to as fiberglass, is a lightweight and incredibly strong material composed of fine glass fibers. These fibers are meticulously woven together to create a fabric that is both flexible and robust. Its unique properties make it an indispensable component in various sectors, from construction to aerospace.