Dense-Glass or D-Glass Fibre,

Dense-Glass or D-Glass Fibre

Introduction

Definition of D-Glass fibre

D-glass fibre, short for “dense-glass” fibre, is a high-performance material renowned for its exceptional strength and durability. Unlike conventional glass fibres, D-glass fibre boasts a denser structure, making it a preferred choice in demanding applications.

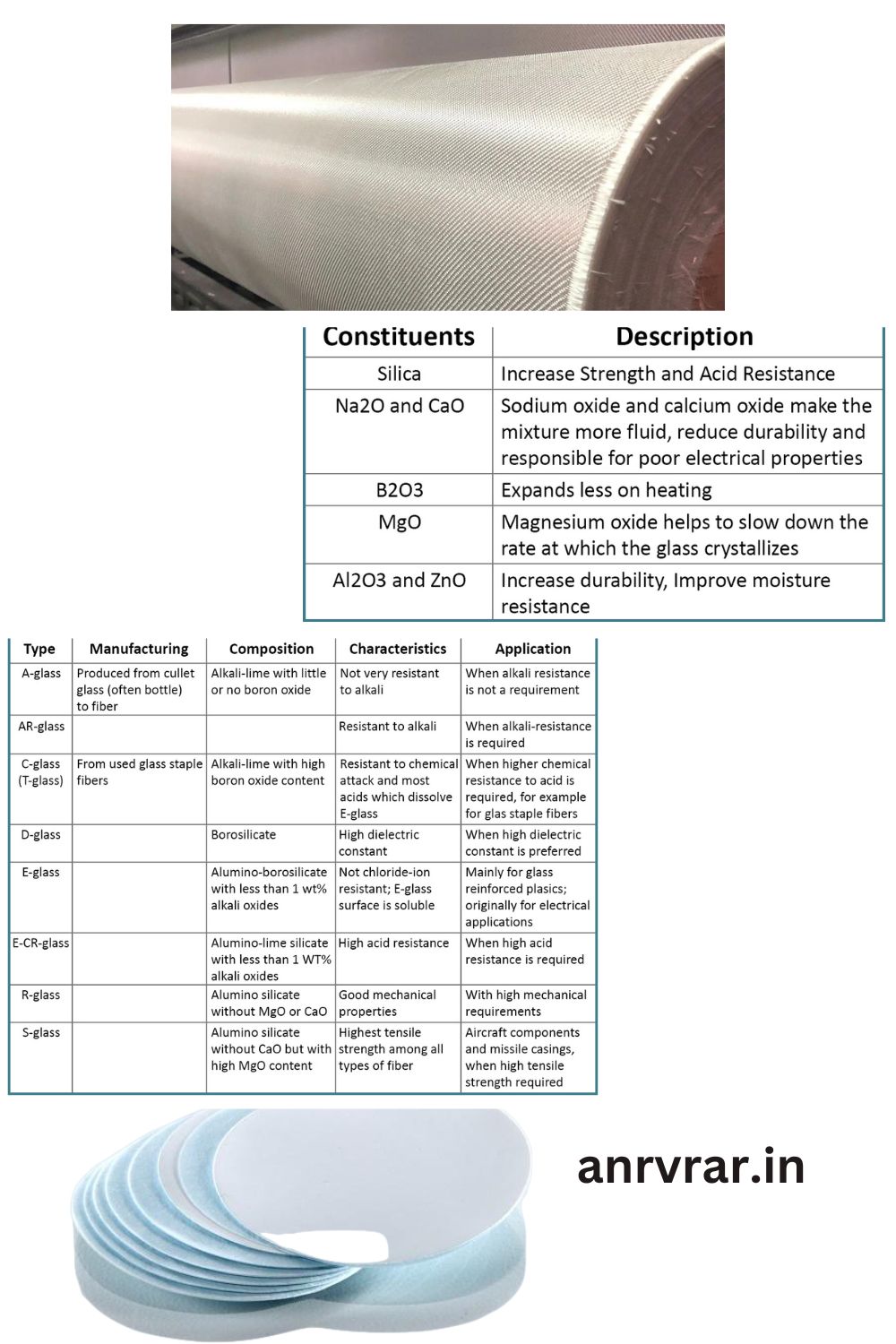

Composition of D-Glass Fibre

In the realm of advanced materials, D-Glass Fibre stands as a paragon of innovation and strength. Let’s embark on a journey to unravel the intricate composition that forms the backbone of this extraordinary substance.

Crafting D-Glass Fibre

Silica

At the heart of D-Glass Fibre lies the omnipresent silica, a key component lending resilience and durability. Silica, sourced meticulously, ensures a robust foundation for the fibre, promising unmatched performance.

Reinforcing with Alumina

To elevate its structural integrity, alumina, a stalwart reinforcement, is intricately woven into the fabric of D-Glass. This strategic addition amplifies tensile strength, making it a stalwart contender in various applications.

Calcium Carbonate

The dance of materials continues with the inclusion of calcium carbonate, injecting balance and stability. This harmonious blend not only enhances the fibre’s performance but also ensures longevity in the face of diverse environmental challenges.

Manufacturing Symphony

Fusion Meltdown

The journey begins with a meticulous fusion of silica, alumina, and calcium carbonate. The concoction undergoes a controlled meltdown, achieving a homogeneous blend crucial for the fibre’s uniformity.

Extrusion Elegance

The molten amalgamation gracefully transitions into the extrusion phase. Here, the concoction transforms into slender strands, each meticulously designed for optimal strength and flexibility.

Cooling Ballet

As the extruded strands dance through cooling chambers, a carefully choreographed cooling process ensues. This phase is paramount, ensuring the fibres solidify with precision, embodying the strength that defines D-Glass Fibre.

Properties of D-Glass Fibre

Strength and Durability

D-Glass Fibre boasts unparalleled strength, making it a go-to choice in industries demanding robust materials. The fibers exhibit exceptional tensile strength, ensuring longevity and reliability in various applications. Whether reinforcing concrete or forming structural components, its durability stands unmatched.

Versatility in Applications

The adaptability of D-Glass Fibre knows no bounds. From everyday items to high-tech industries, its versatile nature shines. This glass variant finds applications in manufacturing, electronics, and even medical devices, proving its worth across diverse sectors.

Chemical Resistance

One of the standout features is D-Glass Fibre resistance to chemicals. This property makes it ideal for environments where exposure to corrosive substances is a concern. Industries dealing with harsh chemicals find solace in the protective shield provided by D-Glass Fibre.

Thermal Insulation

In the world of temperature extremes, D-Glass Fibre emerges as a reliable thermal insulator. Its ability to resist heat transfer ensures stability in varying conditions. This property makes it indispensable in applications where maintaining optimal temperatures is crucial.

Lightweight Design

D-Glass Fibre combines strength with a feather-light composition. This characteristic is a game-changer in industries aiming for high-performance materials without compromising on weight. The lightweight nature of D-Glass Fibre contributes to fuel efficiency in transportation and enhances overall efficiency.

Environmental Sustainability

Embracing D-Glass Fibre isn’t just a choice for performance; it’s a commitment to sustainability. The manufacturing process generates fewer emissions compared to traditional materials, aligning with the global shift towards eco-friendly practices.

Applications

Automotive Industry

D-Glass fiber is widely used to reinforce composite materials in the manufacturing of automotive components. It enhances the strength and durability of parts while reducing overall weight, contributing to improved fuel efficiency.

Aerospace Industry

In the aerospace sector, D-Glass fiber composites are employed to construct lightweight yet strong components, such as aircraft panels, wings, and fuselage sections.

Construction and Infrastructure

D-Glass fibers are added to concrete to increase its tensile strength, impact resistance, and durability. This is particularly useful in construction applications where reinforced concrete is needed to withstand various environmental conditions.

Electronics and Electrical Applications

D-Glass fibers are used in the fabrication of PCBs to provide reinforcement and enhance the mechanical strength of the boards.

Insulation

D-Glass fibers are employed in electrical insulation materials due to their high dielectric strength and resistance to electrical conductivity.

Sporting Goods

D-Glass fibers find applications in the production of sporting equipment such as tennis rackets, fishing rods, and hockey sticks. The fibers contribute to the lightweight and durable nature of these products.

Wind Energy

D-Glass fiber composites are utilized in the construction of wind turbine blades. The material’s strength, flexibility, and resistance to environmental factors make it suitable for withstanding the stresses experienced in wind energy applications.

Marine Industry

D-Glass fibers are used in the construction of boat hulls and other marine components. The corrosion-resistant nature of glass fibers makes them ideal for marine applications.

Military and Defense

D-Glass fibers are employed in the development of lightweight ballistic protection materials, providing a balance between protection and mobility for military personnel and vehicles.

Orthopedic Devices

D-Glass fibers are used in orthopedic implants and devices due to their biocompatibility and strength. They can be incorporated into materials for bone fixation devices and prosthetics.

Pipes and Tanks

D-Glass fibers are used to reinforce pipes and tanks in various industrial settings. This reinforcement improves the structural integrity and longevity of these components.

Luggage and Backpacks

D-Glass fibers contribute to the strength and durability of luggage and backpacks, making them resilient to wear and tear.

The versatile properties of D-Glass fibers make them valuable across a wide range of industries, contributing to the development of lightweight, strong, and durable materials.

Advantages Over Other Fibres

Why D-Glass Fibre Takes the Lead

Durability

D-Glass Fibre boasts unparalleled durability, making it a frontrunner in various applications. Its robust structure ensures longevity, withstanding wear and tear even in the most demanding conditions.

Tensile Strength

One of the key distinguishing features of D-Glass Fibre is its exceptional tensile strength. This attribute is pivotal in applications where the material is subjected to constant tension, providing a reliable and enduring solution.

Maintaining Composure Under Heat

Heat Resistance

D-Glass Fibre is engineered to handle high temperatures with finesse. Its outstanding heat resistance makes it a top choice for applications where maintaining structural integrity under elevated temperatures is imperative.

Thermal Stability

Whether it’s scorching heat or freezing cold, D-Glass Fibre remains thermally stable. This makes it a versatile option for projects exposed to extreme environmental conditions.

Challenges and Limitations

D-Glass Fiber Mass Challenge

One of the foremost challenges lies in the substantial weight of D-Glass Fiber. Industries demand lightweight materials for enhanced efficiency. Tackling this predicament is paramount for its widespread adoption. Engineers and researchers are tirelessly working to formulate composite blends that retain the strength of D-Glass Fiber while significantly reducing its weight.

Temperature Sensitivity in D-Glass Fiber Applications

D-Glass Fiber sensitivity to temperature fluctuations poses a significant limitation. In environments with extreme heat or cold, the material’s performance might be compromised. Innovators are focusing on developing coatings and treatments to mitigate temperature sensitivity, ensuring optimal functionality across diverse conditions.

Durability in D-Glass Fiber

Durability concerns loom large in the realm of D-Glass Fiber applications. Industries relying on robust materials demand longevity and resilience. Researchers are channeling efforts into refining the manufacturing processes to bolster the structural integrity of D-Glass Fiber, addressing concerns and paving the way for its broader acceptance.https://en.wikipedia.org/wiki/Glass_fiber

FAQs about Properties of D-Glass Fibre

Is D-Glass Fibre eco-friendly?

Absolutely! D-Glass Fibre aligns with environmental goals, featuring a manufacturing process that minimizes emissions and promotes sustainability.

Can it replace traditional construction materials?

Yes, D-Glass Fibre strength and durability make it a viable alternative to conventional materials in construction, providing enhanced performance.

How does D-Glass Fibre contribute to fuel efficiency?

The lightweight design of D-Glass Fibre reduces the overall weight of structures and vehicles, leading to improved fuel efficiency.

Are there limitations to D-Glass Fibre?

While highly versatile, D-Glass Fibre may not be suitable for extremely high-temperature applications where other materials excel.

What industries benefit the most from D-Glass Fibre?

Aerospace, automotive, and construction industries reap significant benefits from D-Glass Fibre due to its strength, versatility, and lightweight properties.

Is D-Glass Fibre cost-effective?

Initially, the cost may be higher, but the long-term benefits, including durability and reduced maintenance, make it a cost-effective choice.