Aromatic Polyamide Resins and Applications

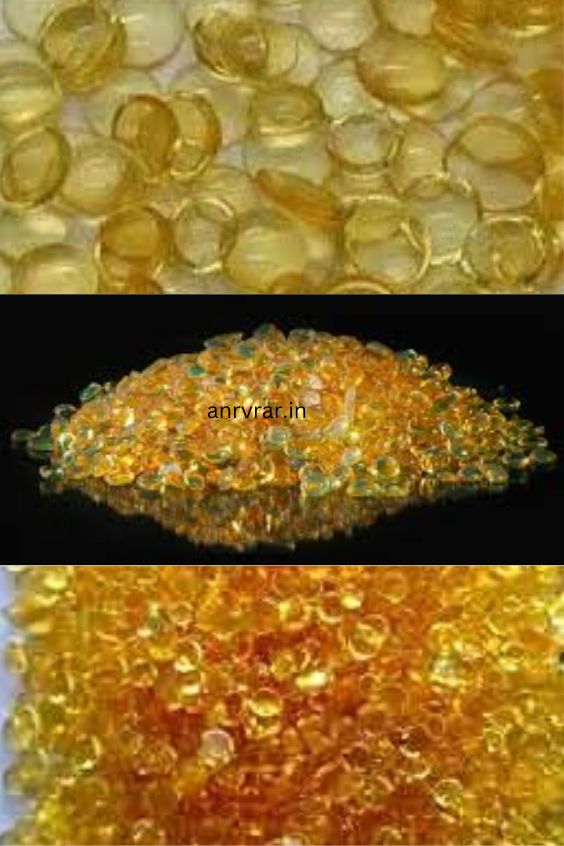

Aromatic Polyamide Resins.

1. Introduction of Aromatic Polyamide Resins

Aromatic polyamide resins, often referred to as aramids, are advanced polymeric materials known for their exceptional strength, heat resistance, and chemical stability. These resins play a critical role in industries where performance and durability are paramount, such as aerospace, automotive, and protective textiles.

What are Polyamide Resins?

Polyamide resins, or nylons, are polymers containing amide linkages (-CONH-) in their molecular structure. They can be either aliphatic (non-aromatic) or aromatic, with the latter offering superior mechanical properties. Aliphatic polyamides, like Nylon 6, are widely used for everyday applications, whereas aromatic polyamides are reserved for more demanding environments.

What Makes Aromatic Polyamides Unique?

The defining feature of aromatic polyamides is their structure, which includes benzene rings along the polymer backbone. This “aromaticity” makes the material more rigid, heat-resistant, and chemically stable compared to their aliphatic counterparts. The result? A polymer that can withstand extreme conditions.

2.Types of Aromatic Polyamide Resins

Aramid Fibers

- Kevlar:Famous for its use in bulletproof vests and protective gear due to its high tensile strength.

- Nomex:Known for flame-resistant properties, making it ideal for firefighters’ suits and industrial applications.

Thermoplastic Aromatic Polyamides

These materials soften upon heating and can be reshaped, making them valuable in coatings, 3D printing, and injection molding.

3.Chemical Structure of Aromatic Polyamides

The chemical backbone of aromatic polyamides contains repeating aromatic (benzene) rings connected by amide bonds. This configuration not only improves rigidity but also contributes to the material’s excellent thermal stability and resistance to solvents.

4.How Aromatic Polyamides Are Synthesized

Aromatic polyamides are typically synthesized through polymerization of aromatic diamines and dicarboxylic acids. The process requires high precision, as even small variations can affect the material’s final properties.

5.Applications in Different Industries

- Aerospace and Automotive:Used in lightweight, heat-resistant components.

- Electronics:Found in insulating films and wiring.

- Textiles:Integral in producing protective clothing like fireproof uniforms and bullet-resistant fabrics.

6.Performance Characteristics of Aromatic Polyamide Resins

High-Temperature Resistance

Aromatic polyamides can withstand temperatures beyond 500°F (260°C) without degrading.

Chemical Stability

They resist exposure to acids, solvents, and moisture, making them perfect for harsh environments.

Lightweight yet Strong

Despite their strength, aromatic polyamides are lightweight, contributing to energy efficiency in transportation applications.

7.Advantages of Using Aromatic Polyamides

Compared to aliphatic polyamides, aromatic variants offer superior mechanical properties, better flame resistance, and enhanced durability. This makes them indispensable in high-performance applications.

8.Challenges in Working with Aromatic Polyamides

While aromatic polyamides excel in performance, they come with some challenges, such as complex production processes and higher costs. Additionally, precise manufacturing conditions are needed to achieve optimal properties.

9.Aromatic Polyamides vs. Other Resins

When compared to other resins like epoxy or polyurethane, aromatic polyamides stand out for their mechanical strength, heat resistance, and chemical stability. These properties make them ideal for critical applications in extreme conditions.

10.FAQs About Aromatic Polyamide Resins

1.What are the main types of aromatic polyamides?

The most well-known types are Kevlar and Nomex, used in protective clothing and industrial applications.

2.How are aromatic polyamides different from aliphatic polyamides?

Aromatic polyamides contain benzene rings, making them more heat-resistant and mechanically strong.

3.Are aromatic polyamides recyclable?

Recycling is challenging, but researchers are exploring new methods to improve sustainability.

4.What industries benefit most from aromatic polyamides?

Aerospace, automotive, electronics, and textiles are key industries using aromatic polyamides.

5.What is the future of aromatic polyamides?

The development of eco-friendly alternatives and applications in green energy is shaping the future of these materials.