Aliphatic Polyurethane Resin

Aliphatic Polyurethane Resin

1.Introduction

What is Aliphatic Polyurethane Resin?

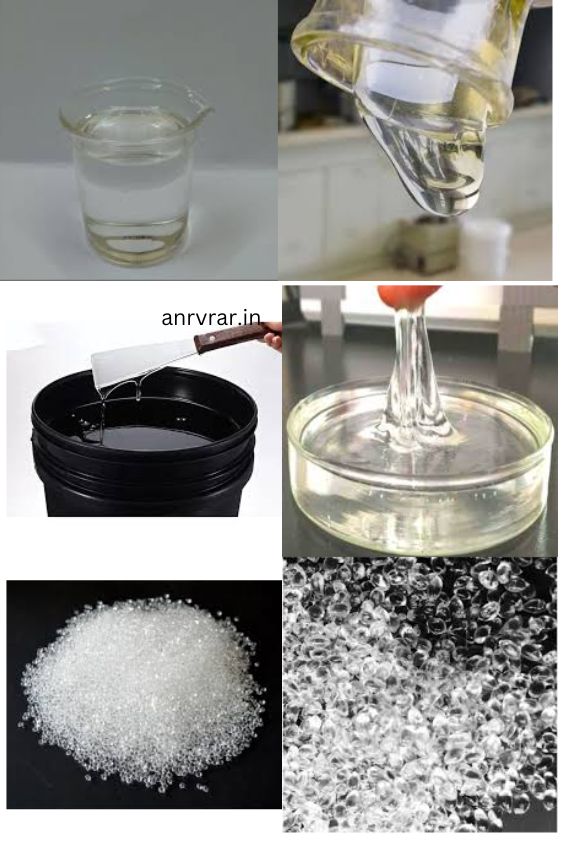

Aliphatic polyurethane resin is a versatile, high-performance polymer used extensively across various industries. It is a type of polyurethane known for its exceptional durability, resistance to environmental factors, and long-lasting performance. Unlike aromatic polyurethane resins, which may degrade when exposed to ultraviolet (UV) light, aliphatic polyurethane resins retain their color and physical properties over time, making them ideal for outdoor and high-exposure applications.

Historical Development and Evolution

The development of aliphatic polyurethane resin traces back to advancements in polymer chemistry in the mid-20th century. Initially used in niche applications, the material gained popularity as industries sought more durable and weather-resistant coatings and materials. Over the decades, continuous research and development have led to the widespread adoption of aliphatic polyurethane resins in various fields, including automotive, construction, and marine industries.

2.Chemical Composition and Properties

Basic Chemical Structure

The chemical structure of aliphatic polyurethane resin is characterized by the presence of aliphatic isocyanates, which form the backbone of the polymer chain. This structure contributes to the resin’s superior UV stability and resistance to yellowing compared to aromatic polyurethane resins, which are based on aromatic isocyanates.

Key Components and Their Functions

Aliphatic polyurethane resin typically consists of two main components: a polyol and an isocyanate. The polyol provides the flexibility and toughness of the resin, while the isocyanate reacts with the polyol to form the polymer chain, resulting in a hard and durable material. Additives such as UV stabilizers, pigments, and fillers are often incorporated to enhance specific properties like color retention, flexibility, or abrasion resistance.

Physical Properties of Aliphatic Polyurethane Resin

One of the standout features of aliphatic polyurethane resin is its exceptional durability. It can withstand extreme weather conditions, including high temperatures, humidity, and exposure to chemicals and pollutants. This makes it an ideal choice for outdoor applications where long-term performance is required.

Solids by volume (v / v): 51%

Application temperature: 10 -25ºC.

Specific weight: 1.2-1.3 g / g / ml

Viscosity 25ºC in CF4: 100-120 sec.

3.Types of Aliphatic Polyurethane Resin

Two-Component Systems

Advantages and Disadvantages

Two-component aliphatic polyurethane systems consist of a polyol and an isocyanate, which are mixed just before application. This type of system offers excellent control over the curing process and allows for the formulation of coatings with specific properties. However, the need for precise mixing and application can be a drawback, requiring skilled labor and specialized equipment.

One-Component Systems

Use Cases and Benefits

One-component systems, on the other hand, are pre-mixed and ready to use. They cure upon exposure to moisture in the air, making them more convenient for certain applications. While they may not offer the same level of customization as two-component systems, they are easier to apply and are often used in DIY and smaller-scale projects.

4.Applications of Aliphatic Polyurethane Resin

Protective and Decorative Uses

Aliphatic polyurethane resin is widely used in industrial coatings for both protective and decorative purposes. Its ability to form a tough, durable film that resists chemicals, abrasion, and environmental degradation makes it ideal for use on machinery, pipelines, and infrastructure.

Paints and Finishes

In the automotive industry, aliphatic polyurethane resin is commonly used in paints and finishes due to its superior gloss retention and resistance to fading. It provides a long-lasting, aesthetically pleasing finish that can withstand the rigors of daily use and exposure to the elements.

Floor Coatings and Waterproofing

In construction, aliphatic polyurethane resins are often used in floor coatings and waterproofing systems. Their durability and resistance to heavy traffic, chemicals, and moisture make them an excellent choice for commercial and industrial flooring, as well as roofing and other waterproofing applications.

Boat Hulls and Deck Coatings

The marine industry benefits from the use of aliphatic polyurethane resins in coatings for boat hulls and decks. These resins provide excellent resistance to saltwater, UV radiation, and physical impact, ensuring that vessels remain in top condition for longer periods.

5.Benefits of Aliphatic Polyurethane Resin

Longevity and Durability

One of the primary benefits of aliphatic polyurethane resin is its longevity. Products and coatings made from this material last significantly longer than those made from many other materials, reducing the need for frequent maintenance or replacement.

Resistance to Environmental Factors

Aliphatic polyurethane resin is highly resistant to environmental factors such as UV light, chemicals, and temperature extremes. This makes it suitable for use in a wide range of environments, from tropical climates to harsh industrial settings.

Versatility in Application

The versatility of aliphatic polyurethane resin is another significant advantage. It can be used in a variety of forms, including coatings, adhesives, sealants, and elastomers, and is compatible with many substrates, including metal, wood, concrete, and plastics.

Cost-Effectiveness

Despite its high-performance characteristics, aliphatic polyurethane resin is cost-effective. Its durability reduces the need for frequent repairs or replacements, offering long-term savings for businesses and consumers alike.

6.Challenges and Limitations

Environmental Impact and Sustainability Concerns

While aliphatic polyurethane resin offers many benefits, it is not without its environmental concerns. The production and disposal of polyurethane materials can have negative environmental impacts, particularly in terms of resource consumption and pollution. Efforts are ongoing to develop more sustainable alternatives and improve the environmental footprint of polyurethane products.

Application Challenges

Applying aliphatic polyurethane resin, especially in two-component systems, requires precision and expertise. Incorrect mixing or application can lead to suboptimal performance, necessitating careful handling and specialized equipment.

Cost Factors

Although generally cost-effective in the long run, the initial cost of aliphatic polyurethane resin can be higher than some alternatives. This can be a barrier for smaller projects or budget-conscious consumers, particularly when factoring in the cost of specialized application tools and skilled labor.

8.Future of Aliphatic Polyurethane Resin

Innovations in Composition

As research and development in polymer chemistry continue, we can expect to see innovations in the composition of aliphatic polyurethane resin. These advancements may lead to materials with even better performance characteristics, such as increased flexibility, higher strength, or enhanced sustainability.

Sustainable Alternatives

Sustainability is a growing concern across all industries, and polyurethane production is no exception. The development of bio-based or recyclable polyurethanes is a promising area of research that could help reduce the environmental impact of these materials in the future.

Expanding Applications

As the properties of aliphatic polyurethane resin continue to be refined, its range of applications is likely to expand. New uses in emerging industries such as renewable energy, advanced electronics, and smart materials could drive further demand for this versatile resin.

9.FAQs

9.1.What makes aliphatic polyurethane resin different from aromatic polyurethane resin?

Aliphatic polyurethane resin differs from aromatic polyurethane resin primarily in its resistance to UV light and color stability. While aromatic resins tend to yellow and degrade when exposed to sunlight, aliphatic resins maintain their color and integrity over time, making them better suited for outdoor and high-exposure applications.

9.2.Can aliphatic polyurethane resin be used in high-temperature environments?

Yes, aliphatic polyurethane resin can be used in high-temperature environments. It is designed to withstand a wide range of temperatures without losing its structural integrity or performance, making it suitable for various industrial and automotive applications.

9.3.How does UV exposure affect aliphatic polyurethane resin?

Aliphatic polyurethane resin is highly resistant to UV exposure, which means it does not degrade, yellow, or lose its properties when exposed to sunlight. This makes it ideal for applications where long-term exposure to the sun is a factor, such as in outdoor coatings and automotive finishes.

9.4.Is aliphatic polyurethane resin eco-friendly?

While aliphatic polyurethane resin offers many performance benefits, its environmental impact is a concern. The production process can be resource-intensive, and the material is not always biodegradable. However, research is ongoing to develop more sustainable versions of polyurethane resins, including bio-based options.

9.5.What are the maintenance requirements for surfaces coated with aliphatic polyurethane resin?

Surfaces coated with aliphatic polyurethane resin typically require minimal maintenance. Regular cleaning and occasional inspections for wear or damage are usually sufficient to keep the coating in good condition. The material’s durability and resistance to environmental factors help reduce the need for frequent maintenance or repairs.https://microcementosonline.com/en/aliphatic-polyurethane-resin.html