A-Glass Fibers,Advantages,Properties,

A-Glass Fibers

Introduction

A-Glass Fibers, or advanced glass fibers, are a type of composite material renowned for their exceptional strength and resilience. These fibers are crafted from a specific type of glass, undergoing a meticulous manufacturing process to achieve their unique properties.

Manufacturing Process

In the vast realm of industrial materials, A-Glass fibers stand out as a versatile and essential component. Understanding the intricacies of their manufacturing process provides valuable insights into their properties and applications. Let’s delve into the fascinating journey of how A-Glass fibers come to life.

Raw Materials Selection

To kickstart the A-Glass fiber manufacturing process, meticulous attention is given to raw material selection. High-quality silica sand, limestone, and other additives create the foundation for these robust fibers. The careful curation of raw materials sets the stage for the exceptional durability A-Glass fibers are known for.

Melting

The selected raw materials undergo a high-temperature melting process, typically exceeding 1700 degrees Celsius. This extreme heat transforms the materials into molten glass, a crucial intermediary in the journey from raw components to resilient A-Glass fibers.

Fiberization

Fiberization is the pivotal step where molten glass takes its final form as A-Glass fibers. Through intricate spinning processes, the molten glass is extruded into thin strands, creating fibers with remarkable tensile strength. This precision ensures that each fiber meets the stringent quality standards required for diverse industrial applications.

Sizing Application

Sizing, a specialized coating, is applied to the freshly formed A-Glass fibers. This coating enhances the fibers’ stability and compatibility with various matrices, ensuring optimal performance in composite materials and reinforcing applications.

Cooling and Collection

After sizing application, the fibers undergo a controlled cooling process, solidifying their structure and properties. The carefully managed collection of A-Glass fibers ensures uniformity and consistency, vital for their widespread use in industries ranging from construction to automotive.

Quality Control

Quality control is integral to the A-Glass fiber manufacturing process. Rigorous testing procedures, including tensile strength assessments and diameter measurements, guarantee that every batch adheres to the highest industry standards. This commitment to quality ensures the reliability and durability of A-Glass fibers in diverse applications.

Properties of A-Glass Fibers

A-Glass fibers, often referred to as alkali-resistant glass fibers, have become indispensable in various industries due to their unique properties. These fibers, composed of specific raw materials and manufactured through precise processes, offer a range of characteristics that make them versatile and valuable. In this article, we delve into the properties of A-Glass fibers, exploring their composition, physical attributes, and wide-ranging applications.

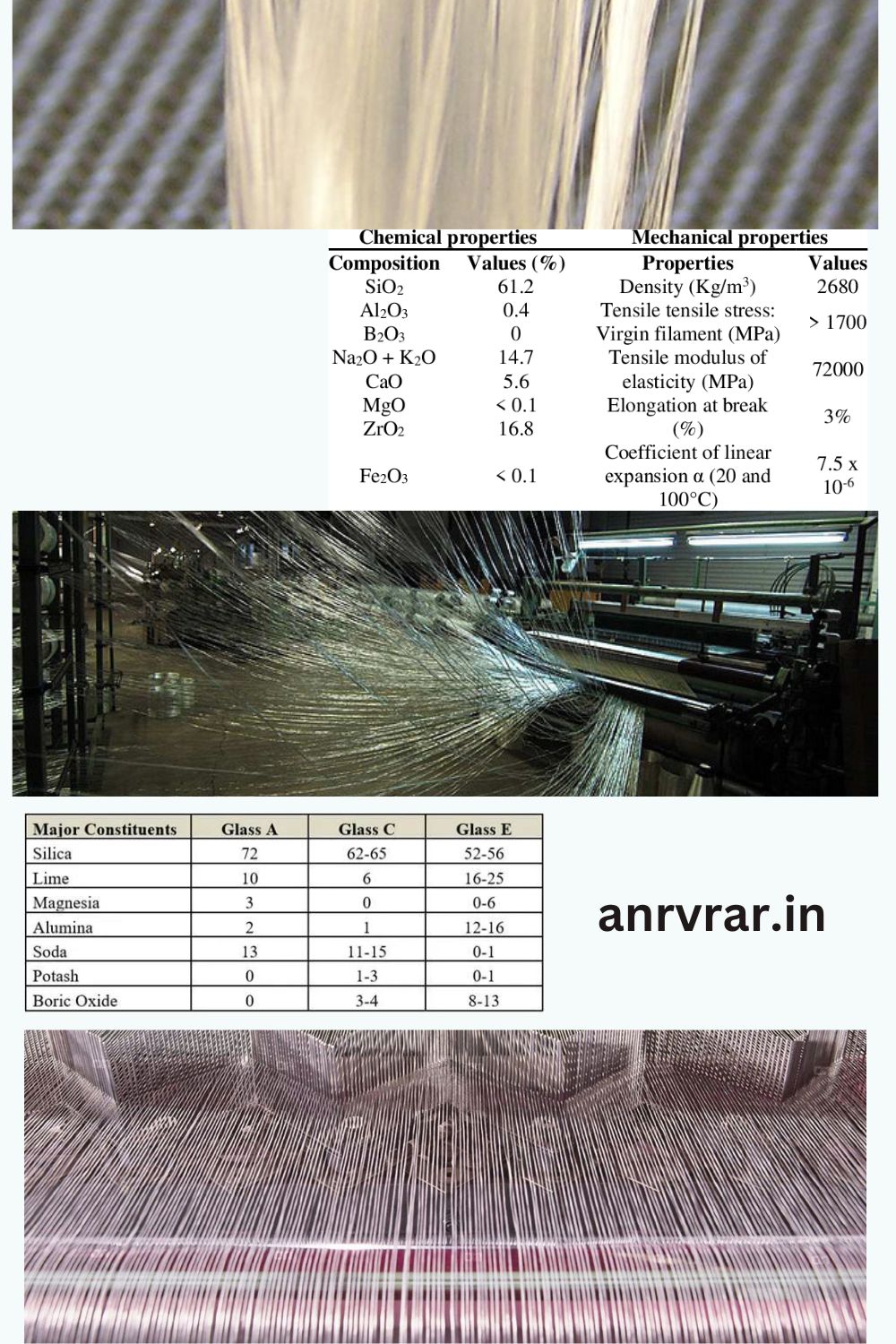

Composition and Manufacturing Process

A-Glass fibers are predominantly composed of silica, alumina, and other alkali oxides. The manufacturing process involves melting the raw materials at high temperatures and then drawing them into fine fibers. This meticulous procedure contributes to the fibers’ exceptional strength and durability, setting them apart in the material landscape.

Physical Properties

Strength and Durability A-Glass fibers boast remarkable tensile strength, making them ideal for applications requiring robust materials. Their durability ensures longevity, making them a preferred choice in construction and engineering.

Flexibility Despite their strength, A-Glass fibers maintain flexibility, allowing them to be molded into various shapes. This characteristic expands their utility in industries demanding adaptable materials.

Weight These fibers are notably lightweight, a crucial factor in industries such as automotive and aerospace, where minimizing weight without compromising strength is paramount.

Electronic Industry

Insulation in Wiring In the electronic industry, A-Glass fibers are employed for insulation in wiring, preventing electrical interference and ensuring the stability of electronic devices.

Thermal Stability The fibers’ ability to withstand high temperatures without compromising structural integrity makes them valuable in electronic applications requiring thermal stability.

Environmental Impact

Recyclability A-Glass fibers are recyclable, aligning with the growing emphasis on sustainable practices. Their recyclability reduces environmental impact and supports eco-friendly manufacturing processes.

Sustainability The use of A-Glass fibers contributes to sustainability efforts, as their composition and manufacturing process have a lower environmental footprint compared to some alternative materials.

Challenges and Innovations

Overcoming Limitations Researchers and manufacturers are continually working to overcome the limitations of A-Glass fibers, such as brittleness, through innovations in production techniques and material enhancements.

Emerging Technologies The field of A-Glass fibers is witnessing advancements in technology, leading to the development of new variants with enhanced properties and broader applications.

Applications of A-Glass Fibers

In the realm of cutting-edge materials, A-Glass fibers stand tall as a versatile and indispensable player. These fibers, derived from alkali-aluminosilicate glass, boast exceptional strength and durability, making them a go-to choice for a myriad of applications across various industries. Let’s delve into the wide array of applications where A-Glass fibers take center stage.

Aerospace

In the aerospace sector, precision and resilience are paramount, and A-Glass fibers emerge as a pivotal component. Reinforcing composites with A-Glass fibers enhances the structural integrity of aircraft components, ensuring optimal performance even under extreme conditions. From fuselages to wings, these fibers contribute to the lightweight yet robust construction of aerospace marvels.

Automotive

The automotive industry, perpetually in pursuit of efficiency and safety, has found a steadfast ally in A-Glass fibers. Incorporating these fibers into vehicle components, such as bumpers and body panels, results in a remarkable reduction in weight without compromising on durability. This not only contributes to fuel efficiency but also enhances overall vehicle safety standards.

Construction Excellence

In the realm of construction, where durability and longevity are non-negotiable, A-Glass fibers play a pivotal role. These fibers reinforce concrete structures, offering enhanced tensile strength and crack resistance. From bridges to high-rise buildings, the integration of A-Glass fibers ensures structural stability, standing the test of time and environmental factors.

Sporting Goods Reinforcement

Athletic prowess demands equipment that can withstand rigorous use, and A-Glass fibers prove instrumental in crafting high-performance sporting goods. From tennis rackets to bicycles, the incorporation of these fibers enhances strength and impact resistance, providing athletes with gear that excels in both form and function.

Marine

In the maritime domain, where vessels navigate challenging waters, the durability of materials is paramount. A-Glass fibers find application in boat construction, reinforcing hulls and ensuring optimal buoyancy. Their resistance to corrosion and harsh marine environments makes them a preferred choice for maritime engineers striving for excellence.

Electronic

A-Glass fibers also play a crucial role in the evolution of electronic devices. Their exceptional insulating properties make them ideal for manufacturing circuit boards and other electronic components. As technology advances, A-Glass fibers continue to underpin the creation of cutting-edge devices, ensuring reliability and longevity.

Renewable Energy Reinforcement

The pursuit of sustainable energy sources has led to increased use of A-Glass fibers in the renewable energy sector. Wind turbine blades, in particular, benefit from the strength and lightweight properties of these fibers, contributing to the efficiency and longevity of renewable energy infrastructure.

Advantages of A-Glass Fibers

A-Glass Fiber Excellence

Inimitable Sturdiness: A-Glass fibers manifest an unparalleled robustness, navigating the labyrinth of structural demands with unparalleled tenacity. This unique attribute ensures longevity and fortitude in the face of adversarial conditions.

Symbiotic Resilience:

The integration of A-Glass fibers engenders a synergistic resilience, forging an amalgamation that withstands external pressures and inclement forces. This dynamic interaction imbues structures with an enduring capacity to weather the storms of time.

Inherent Versatility:

A-Glass fibers boast an intrinsic versatility, embracing a malleability that befits diverse applications. This innate adaptability renders them indispensable across a spectrum of industries, from aerospace engineering to architectural marvels.

Effervescent Thermal Stability:

The effervescent thermal stability inherent in A-Glass fibers elucidates their prowess in dissipating and managing heat. This attribute proves pivotal in applications requiring precision and reliability under varying thermal gradients.

Challenges and Solutions

Across Industries

The versatility of A-Glass fibers finds expression in various industries, including construction, automotive, and aerospace. From reinforcing concrete structures to enhancing the mechanical properties of composite materials, A-Glass fibers have become indispensable.

Alkali Attack

One of the primary challenges faced by A-Glass fibers is the relentless attack from alkali substances. This can compromise the structural integrity of the fibers, leading to reduced performance and lifespan.

Moisture Sensitivity

A-Glass fibers are susceptible to moisture, which can exacerbate their alkali sensitivity. This poses a significant hurdle in environments where exposure to moisture is inevitable.

Adhesion Issues

Ensuring proper adhesion between A-Glass fibers and matrix materials is another challenge. Inadequate adhesion can result in delamination and compromise the overall strength of the composite.

A-Glass Fiber Landscape

To combat the corrosive impact of alkali, innovative alkali-resistant coatings are applied to A-Glass fibers. These coatings act as a protective barrier, preventing the intrusion of alkali substances and enhancing the longevity of the fibers.

Moisture-Resistant Treatments

Addressing the moisture sensitivity of A-Glass fibers involves incorporating moisture-resistant treatments during the manufacturing process. This ensures that the fibers maintain their structural integrity even in humid or wet conditions.

Creating a Sturdy Base

Planters are a popular DIY project, and incorporating A-Glass fibers can take them to the next level. Begin by mixing A-Glass fibers with concrete to create a robust and durable base for your planters. This not only enhances their strength but also ensures longevity, making them perfect for both indoor and outdoor use.

Designing Patterns and Textures

Inject a touch of creativity by experimenting with different patterns and textures using A-Glass fibers. Whether you prefer a smooth finish or a more textured appearance, A-Glass fibers allow you to customize your planters to match your unique style.

Playing with Colors

A-Glass fibers are incredibly versatile and can be easily colored. Experiment with different pigments and dyes to create a vibrant palette for your wall art. This not only adds a pop of color to your space but also ensures that your creation stands out as an original masterpiece.

Building a Solid Foundation

DIY furniture projects, such as tables, can benefit significantly from the incorporation of A-Glass fibers. Mix A-Glass fibers with epoxy resin or wood glue when assembling the table’s components. This not only strengthens the structure but also adds a layer of durability that ensures your furniture lasts for years.https://www.sciencedirect.com/topics/materials-science/glass-fiber

FAQs

How are A-Glass Fibers different from E-Glass Fibers?

Explore the distinctions between A-Glass and E-Glass Fibers, shedding light on their unique properties and applications.

Can A-Glass Fibers be recycled?

Uncover the eco-friendly side of A-Glass Fibers as we discuss recycling possibilities and sustainable practices.

Are A-Glass Fibers suitable for DIY projects?

Discover the potential for creative endeavors as we explore the feasibility of using A-Glass Fibers in do-it-yourself projects.

How do A-Glass Fibers contribute to energy efficiency in buildings?

Explore the role of A-Glass Fibers in making buildings more energy-efficient, reducing environmental impact.

Are A-Glass Fibers Safe for Skin Contact?

Yes, A-Glass fibers are generally safe for skin contact. The fibers are smooth and unlikely to cause irritation. However, it’s advisable to wear protective gear when handling large quantities.

Can A-Glass Fibers Cause Respiratory Issues?

No, when used under normal conditions, A-Glass fibers do not cause respiratory issues. As with any fibers, it’s crucial to follow safety guidelines and use protective equipment in high-exposure scenarios.