Ortho resin,Composition of Ortho Resin,Properties of Ortho Resin,Applications,Future Developments,Chemical Properties of Ortho Resin

Ortho resin

Introduction

Ortho resin, short for orthodontic resin, is a vital material used extensively in the field of dentistry, particularly in orthodontics. It plays a crucial role in modern orthodontic practices and has revolutionized the way orthodontic treatments are conducted. Ortho resin is a type of dental adhesive that bonds various orthodontic appliances to teeth, providing a stable and effective means of correcting dental misalignments and malocclusions. Its unique properties and versatility make it an essential component in the arsenal of orthodontic professionals.

In this comprehensive introduction to ortho resin, we will delve into its composition, properties, applications, and the benefits it offers to both orthodontic practitioners and patients. We will explore its historical development, current state of the art, and future potential in the ever-evolving world of dental materials and orthodontic treatment.

The use of dental adhesives in orthodontics dates back to the mid-20th century. The earliest adhesives were often simple resins or cements that provided only limited bonding capabilities. Over time, research and development efforts led to the creation of more advanced adhesives, and the term “ortho resin” emerged to describe specialized adhesives tailored specifically for orthodontic applications.

Composition of Ortho Resin

Ortho resin is a composite material composed of several key components:

1. Monomers:

Monomers are the building blocks of the resin and are typically acrylic-based. They provide the fluidity and low viscosity necessary for ease of application during bonding procedures.

2. Initiators:

Initiators are responsible for starting the polymerization reaction, transforming the liquid resin into a solid state. Common initiators include benzoyl peroxide or camphorquinone, which are activated by light exposure.

3. Fillers:

Fillers are added to the ortho resin to improve its mechanical properties, such as strength and wear resistance. Common fillers include silica or glass particles.

4. Adhesion promoters: To enhance the bonding capacity of the resin to both the tooth surface and orthodontic appliances, specific adhesion promoters or coupling agents are incorporated into the formulation.

Properties of Ortho Resin

Ortho resin possesses several crucial properties that make it suitable for orthodontic applications:

1. Bond Strength:

Ortho resin exhibits excellent bond strength to enamel and orthodontic appliances, ensuring a secure attachment throughout the treatment period.

2. Viscosity:

Its low viscosity allows for easy application and precise placement, ensuring optimal coverage of the bonding surface.

3. Light-Curing Capability:

Ortho resin is light-curable, meaning it can be activated and polymerized using visible light of specific wavelengths. This feature allows for precise control over the curing process and minimizes the risk of incomplete polymerization.

4. Biocompatibility:

The materials used in ortho resin are carefully selected to ensure biocompatibility, minimizing the risk of adverse reactions or allergic responses in patients.

5. Color Stability:

Ortho resin is designed to resist discoloration over time, ensuring a long-lasting esthetic appearance during treatment.

Applications of Ortho Resin

Ortho resin has a wide range of applications in orthodontic practice:

1. Bonding Brackets:

One of the primary uses of ortho resin is to bond orthodontic brackets to the tooth surface. The resin forms a strong bond between the bracket base and enamel, providing a stable anchor for orthodontic forces.

2. Attaching Bands:

Orthodontic bands, used to anchor appliances like molar bands, are securely attached to teeth using ortho resin.

3. Lingual Attachments:

Ortho resin is used in lingual orthodontics to bond lingual brackets or attachments to the inner surface of teeth, allowing for discreet treatment options.

4. Attaching Retainers:

Ortho resin is utilized to bond fixed or removable retainers to maintain the results of orthodontic treatment.

Future Developments

As technology and dental materials research progress, ortho resin is likely to undergo continuous advancements and refinements. Anticipated developments may include:

1. Novel Monomer Formulations:

Researchers may explore new monomer compositions to further improve bond strength, biocompatibility, and color stability.

2. Enhanced Curing Techniques:

Advancements in light-curing technology may lead to faster and more efficient curing processes.

3. Nanotechnology:

The incorporation of nanomaterials could enhance the mechanical properties of ortho resin, making it even more durable and resilient.

4. Biodegradable Options:

Efforts to develop biodegradable ortho resin could align with the growing focus on environmentally friendly dental materials.

Chemical Composition of Ortho Resin

Ortho resin, also known as orthophthalic resin, is a type of unsaturated polyester resin widely used in various industries for its excellent properties and versatility. In this essay, we will explore the chemical composition of ortho resin, its manufacturing process, and its applications.

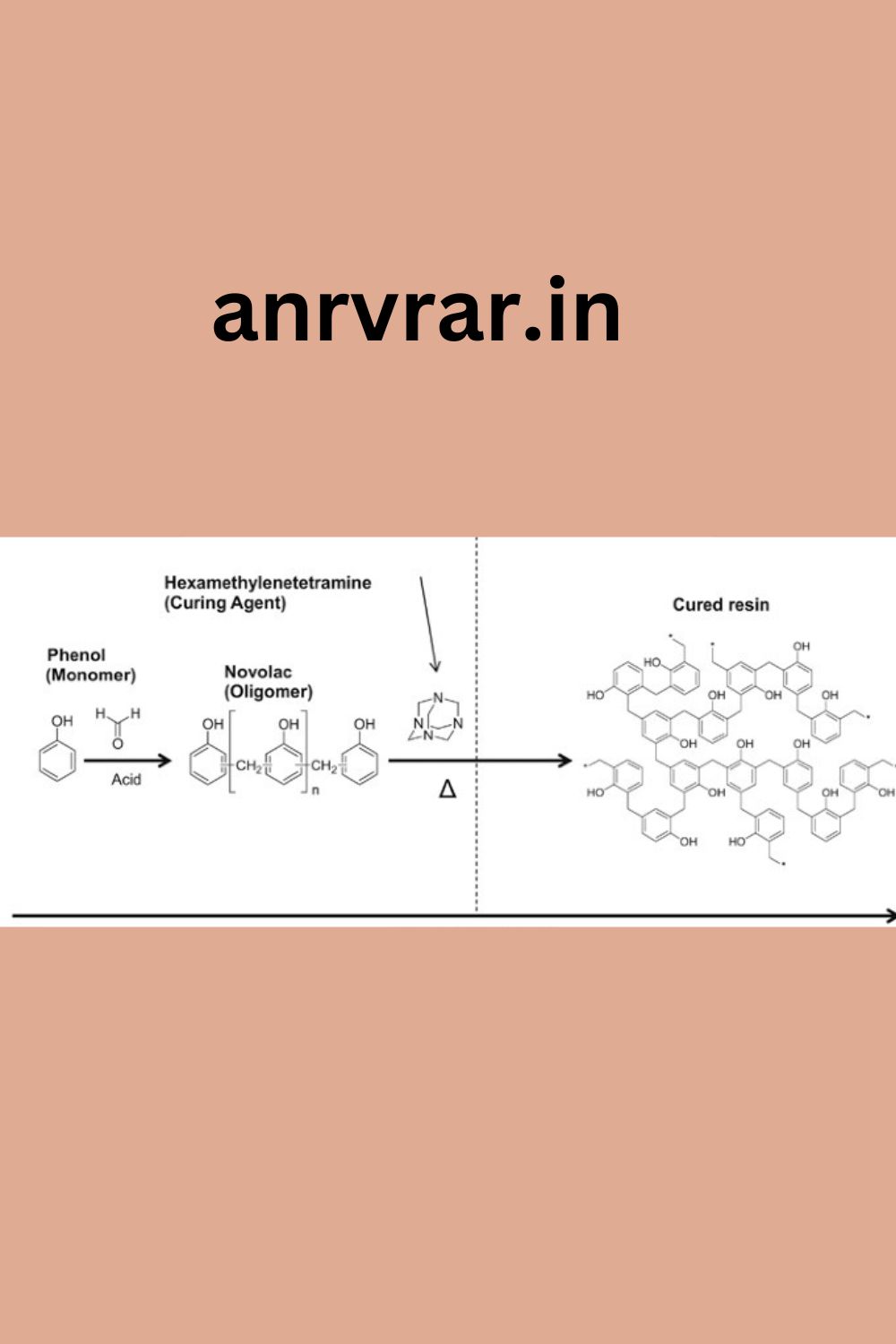

Ortho resin is a thermosetting polymer, which means it undergoes a chemical reaction during curing that forms a crosslinked three-dimensional network, leading to its rigid and durable nature. The primary components of ortho resin are:

Unsaturated Polyester Resin:

The backbone of ortho resin is made up of unsaturated polyester. This polymer is produced through the polycondensation reaction between a diacid (usually orthophthalic acid) and a diol (usually ethylene glycol or propylene glycol). The acid and glycol components combine to form a long-chain polyester molecule with double bonds (unsaturated groups) in the structure.

Styrene Monomer:

To make the ortho resin suitable for its intended applications, it is modified with a reactive diluent, commonly styrene monomer. Styrene acts as a crosslinking agent during the curing process, promoting polymerization and hardening of the resin.

The chemical composition of ortho resin can be further explained by the following reactions involved in its synthesis:

Step 1: Esterification The first step in the production of ortho resin is the esterification reaction, where orthophthalic acid (C8H6O4) reacts with an excess of ethylene glycol (C2H6O2). The reaction can be represented as follows:

n C8H6O4 + m C2H6O2 → [C8H6O4(C2H6O2)m]n + n H2O

In this reaction, n and m represent the degree of polymerization, and [C8H6O4(C2H6O2)m]n denotes the unsaturated polyester backbone.

Step 2: Addition of Styrene Monomer To improve the resin’s handling characteristics and decrease its viscosity, styrene monomer is added to the unsaturated polyester. The styrene monomers become interspersed between the polyester chains, forming a homogeneous solution.

Step 3: Crosslinking (Curing) The curing of ortho resin occurs through a process called free-radical polymerization. During curing, a catalyst (usually organic peroxides) is added to initiate the crosslinking reaction. The peroxide decomposes to form free radicals, which attack the unsaturated double bonds in the polyester and styrene molecules, leading to the formation of a three-dimensional crosslinked network.

The overall chemical composition of the cured ortho resin can be depicted as follows:

[-OC-C6H4-CO-O-CH2-CH2-O-]n + m CH2=CH-C6H5 → [-OC-C6H4-CO-O-CH2-CH2-O-CH2-CH(C6H5)-]n

The degree of crosslinking depends on various factors, including the concentration of the catalyst, curing temperature, and time.

Applications:

Ortho resin finds widespread use in numerous industries due to its advantageous properties, such as high strength, excellent chemical resistance, low shrinkage, and ease of processing. Some common applications include:

Fiberglass Reinforced Plastics (FRP):

Ortho resin is commonly used as a matrix material in FRP composites. When combined with fiberglass reinforcements, it produces strong and lightweight materials used in boat building, automotive components, aerospace parts, and various structural applications.

Laminates and Coatings:

Ortho resin is used to manufacture laminates and coatings for a wide range of products, such as pipes, tanks, and corrosion-resistant equipment in the chemical processing industry.

Electrical Components:

The resin’s electrical insulating properties make it suitable for encapsulating and potting electronic components, electrical insulators, and various electrical enclosures.

Construction Materials:

Ortho resin is used in construction applications like architectural panels, façades, and decorative elements due to its weather resistance and dimensional stability.

Chemical Properties of Ortho Resin

Ortho resin, also known as orthophthalic resin or unsaturated polyester resin, is a widely used synthetic polymer material with versatile chemical properties. In this comprehensive overview, we will delve into the chemical aspects of ortho resin, its molecular structure, polymerization process, and applications.

- Introduction to Ortho Resin: Ortho resin belongs to the family of unsaturated polyester resins, which are formed by the condensation polymerization of unsaturated organic acids (such as phthalic anhydride) and diols (usually propylene glycol or ethylene glycol). The result is a viscous, liquid resin with excellent molding capabilities, high resistance to chemicals, and good mechanical properties. These characteristics make it suitable for a wide range of applications in industries like construction, automotive, marine, and aerospace.

- Molecular Structure: Ortho resin consists of a long polymer chain with repeating ester linkages. The key components of its molecular structure are:

Phthalic Anhydride:

A cyclic anhydride derived from phthalic acid, which contributes to the resin’s cross-linking properties.

Diols (e.g., Propylene Glycol): These are dihydric alcohols that provide sites for esterification with phthalic anhydride, leading to the formation of ester bonds in the polymer chain.

Unsaturated Monomers (e.g., Styrene): Ortho resin often includes unsaturated monomers to introduce double bonds along the polymer chain, enabling cross-linking during polymerization.

- Polymerization Process: The polymerization of ortho resin involves two main stages: pre-polymerization and cross-linking. During pre-polymerization, the unsaturated polyester resin and a catalyst (typically an organic peroxide) are mixed with a small amount of an accelerator. The accelerator promotes the formation of free radicals, which initiate the cross-linking process.

In the presence of heat, the catalyst decomposes, releasing free radicals. These free radicals attack the double bonds in the unsaturated monomers, causing them to link together and form a three-dimensional network. This cross-linking reaction continues until the resin solidifies into its final cured state.

- Chemical Properties: a. Resistance to Chemicals: Ortho resin exhibits excellent resistance to a wide range of chemicals, including acids, alkalis, and many organic solvents. This property makes it suitable for applications where exposure to aggressive environments is expected.

- Mechanical Properties: The mechanical properties of ortho resin can be tailored by adjusting the formulation and the curing process. Cured ortho resin has good tensile strength, flexural strength, and impact resistance. However, it may have lower strength and toughness compared to advanced engineering polymers.

- Thermal Stability: The thermal stability of ortho resin depends on the specific formulation and the degree of cross-linking achieved during polymerization. Generally, ortho resin can withstand moderate temperatures, but it may soften and degrade at elevated temperatures.

- Dimensional Stability: Ortho resin exhibits low shrinkage during the curing process, resulting in good dimensional stability in molded products.

- Water Absorption: Like many polymers, ortho resin has the potential to absorb water over time. Proper formulation and post-curing treatments can help minimize water absorption and enhance product durability.

- UV Resistance: Ortho resin may undergo degradation upon prolonged exposure to UV radiation. To enhance UV resistance, manufacturers often add UV stabilizers to the formulation.

- Applications: Ortho resin finds applications in various industries due to its versatile properties. Some common applications include:

- Composites: Ortho resin is widely used as a matrix material in fiberglass reinforced composites. These composites are employed in boat building, automotive parts, aerospace components, and construction materials.

- Marine Industry: Ortho resin’s resistance to water, chemicals, and corrosion makes it a popular choice for marine applications, including boat hulls and decks.

- Construction: It is used in the construction industry for producing corrosion-resistant pipes, tanks, and other infrastructure elements.

- Automotive: Ortho resin is used in the manufacturing of automotive body parts, such as bumpers and hoods, due to its excellent molding capabilities and mechanical properties.

- Electrical Components: The dimensional stability and electrical insulation properties of ortho resin make it suitable for electrical enclosures, insulators, and various electrical components.

- Coatings and Adhesives: Ortho resin is sometimes used as a binder in coatings and adhesives, providing good adhesion and chemical resistance.

Advantage of Ortho Resin

Mechanical Advantages: Ortho resin possesses excellent mechanical properties, making it highly sought after in engineering and construction applications. These advantages include: a. High Strength: Ortho resins exhibit significant tensile and flexural strength, making them ideal for load-bearing structures and components. b. Stiffness: It provides good rigidity, ensuring that molded parts maintain their shape and resist deformation. c. Impact Resistance: Ortho resin exhibits good impact resistance, which is crucial for components exposed to mechanical stresses. d. Fatigue Resistance: The material shows resistance to fatigue, allowing it to withstand repeated loading cycles without significant degradation.

Chemical Advantages: Ortho resin is known for its exceptional chemical resistance, which makes it suitable for use in harsh environments. Some key chemical advantages are as follows: a. Corrosion Resistance: The material can withstand exposure to various chemicals, making it an excellent choice for applications in chemical processing, marine environments, and storage tanks. b. Water Resistance: Ortho resin is highly impermeable to water, making it ideal for applications in wet environments, such as boat hulls and swimming pools. c. UV Resistance: It shows good resistance to UV radiation, making it suitable for outdoor applications without significant degradation or color fading.

Economic Advantages: Ortho resin offers economic benefits to various industries, contributing to its widespread use. These economic advantages include: a. Cost-Effective: Ortho resin is relatively inexpensive compared to other high-performance resins, making it a cost-effective choice for large-scale production. b. Easy to Process: It is relatively easy to handle and process, allowing for efficient and streamlined manufacturing processes, reducing production time and costs. c. Low Shrinkage: Ortho resin exhibits minimal shrinkage during curing, resulting in less waste and higher production yields.

Environmental Advantages: The environmental advantages of ortho resin contribute to sustainable manufacturing and reduced environmental impact. Some key benefits are as follows: a. Recyclable: Ortho resin can be recycled, reducing the amount of waste generated in manufacturing processes and promoting circular economy principles. b. Low Emissions: During processing and curing, ortho resin emits low levels of volatile organic compounds (VOCs), contributing to better air quality and reduced pollution.

Disadvantage of Ortho Resin .

Susceptibility to Staining: One of the major disadvantages of orthodontic resin is its susceptibility to staining over time. The resin material can absorb pigments from various sources, including food, beverages, and tobacco products. As a result, the appearance of the bonded brackets or dental restorations may degrade, leading to discoloration and aesthetic concerns for patients. To minimize this issue, patients are often advised to avoid highly pigmented substances and maintain proper oral hygiene practices.

Wear and Tear: Orthodontic resin can experience wear and tear over time, especially in areas of high occlusal or chewing forces. As a result, the bonded brackets or dental restorations may gradually deteriorate, compromising their integrity and effectiveness. Frequent replacement or repair of the resin may be necessary, adding to the overall treatment cost and inconvenience for the patients.

Material Shrinkage: Orthodontic resin is known to undergo a certain degree of shrinkage during the curing process. This shrinkage can lead to marginal gaps between the resin and the tooth surface, creating potential sites for bacterial accumulation and secondary decay. Dentists often use techniques and materials to minimize shrinkage, but complete elimination of this issue remains challenging.

Polymerization Stress: The curing process of orthodontic resin involves the conversion of the material from a soft state to a hardened state through polymerization. This transformation can generate polymerization stress within the resin, leading to adhesive failure, microleakage, and debonding of brackets. Polymerization stress can also contribute to tooth sensitivity and discomfort for patients, especially in large restorations.

Allergic Reactions: Although rare, some patients may develop allergic reactions to the components present in orthodontic resin. For instance, the monomers, such as Bis-GMA (Bisphenol A-glycidyl methacrylate), may cause sensitivity or allergic responses in susceptible individuals. Dentists should be aware of these potential reactions and conduct appropriate tests if patients exhibit any signs of allergies.

Bonding to Moist Surfaces: Achieving a strong and durable bond between orthodontic resin and tooth surfaces requires a dry and clean environment. Moisture contamination during the bonding procedure can weaken the bond, leading to bracket failure or compromised restorations. Maintaining a dry field during bonding can be challenging, especially in patients with excessive saliva flow.

Esthetic Limitations: While orthodontic resin comes in various shades to match the natural tooth color, achieving a perfect esthetic match can be difficult, especially for more challenging cases or when dealing with discolored teeth. In such situations, the bonded brackets or restorations may be more noticeable, affecting the patient’s self-esteem and satisfaction with the treatment.

Limited Strength and Durability: Compared to other dental materials like metal brackets or ceramic restorations, orthodontic resin has inherent limitations in terms of strength and durability. It may not withstand extreme occlusal forces or stress as effectively, potentially leading to fractures or failures over time. Dentists often need to carefully assess the patient’s occlusion and oral habits before choosing orthodontic resin for specific cases.

Technique Sensitivity: The successful application of orthodontic resin depends on the dentist’s skill and technique. Achieving optimal bonding and restoration results can be challenging and require proper training and experience. Inadequate bonding or restoration procedures may lead to reduced treatment effectiveness and patient dissatisfaction.

Long-Term Stability: Although orthodontic resin is widely used for its bonding capabilities, its long-term stability remains a concern. Over time, the resin may weaken or degrade due to factors like aging, thermal cycling, and exposure to oral conditions. This deterioration may necessitate re-bonding or replacement, adding to the overall treatment cost and patient inconvenience.

Limitations of Ortho Resin

Limited Temperature Resistance: One of the primary limitations of ortho resin is its relatively low-temperature resistance compared to other advanced resin systems. When exposed to high temperatures, ortho resin can undergo thermal degradation, leading to a decrease in mechanical properties and increased susceptibility to deformation or cracking. This makes it unsuitable for high-temperature applications or environments where thermal stability is crucial.

Brittleness: Ortho resin can be inherently brittle, particularly when it is fully cured. This brittleness can lead to reduced impact resistance and make the material more susceptible to cracking or fracture under dynamic loading conditions. In applications requiring high toughness or resistance to impact, alternative resin systems may be more appropriate.

Chemical Vulnerability: Ortho resin is susceptible to attack by a wide range of chemicals, including acids, bases, and some solvents. This chemical vulnerability limits its use in environments where exposure to corrosive substances is a concern. In such cases, more chemically resistant resin systems, such as epoxy or vinyl ester resins, might be preferable.

UV Degradation: Ortho resin is sensitive to ultraviolet (UV) radiation, which can lead to photodegradation and surface chalking over time. This UV degradation can cause aesthetic issues and a reduction in mechanical properties, making it less suitable for outdoor or exposed applications unless appropriate UV stabilizers are added.

Dimensional Stability: Ortho resin may experience significant dimensional changes during curing and cooling, leading to issues with part accuracy and precision. This limitation is particularly crucial in applications where tight tolerances and precise dimensions are required.

Shrinkage: During the curing process, ortho resin can undergo volumetric shrinkage, which can lead to internal stress within the cured part. This shrinkage may cause warping, distortion, or even delamination if not adequately controlled, especially in larger and thicker parts.

Environmental Impact: Ortho resin is not considered environmentally friendly. Its production involves the use of non-renewable resources, and it can release volatile organic compounds (VOCs) during curing, contributing to air pollution. Additionally, disposal of ortho resin waste can be challenging, as it may require specialized treatment due to its non-biodegradable nature.

Long Cure Time: Ortho resin typically has a longer cure time compared to some other resin systems. This extended curing period can slow down production processes and may require additional energy and resources for heating and curing equipment.

Limited Fire Resistance: Ortho resin is not inherently fire-resistant, and it can undergo combustion when exposed to high heat or flames. In applications where fire safety is critical, using flame-retardant additives or considering alternative fire-resistant materials may be necessary.

Adhesion Challenges: Achieving strong adhesion between ortho resin and certain substrates, such as metals or certain plastics, can be challenging. Surface preparation and the use of appropriate primers are often necessary to improve adhesion properties.

Shrinkage Value of Ortho Resin

Introduction to Ortho Resin: Ortho resin is a dental composite made up of a matrix (typically a resin material) and fillers (such as glass or ceramic particles). These composites are designed to mimic the appearance and mechanical properties of natural teeth while providing the necessary adhesion and strength for orthodontic applications.

Shrinkage in Ortho Resin: Shrinkage in ortho resin refers to the reduction in volume or size of the composite material during the curing process. This phenomenon occurs due to the polymerization reaction that takes place when the resin is exposed to light or chemical activation.

Causes of Shrinkage: The primary cause of shrinkage in ortho resin is the polymerization reaction itself. As the resin monomers react to form a polymer network, they undergo a decrease in molecular spacing, leading to a reduction in volume.

Types of Shrinkage: Ortho resin can experience two types of shrinkage: a. Polymerization Shrinkage: This occurs during the initial curing process when the resin converts from a monomeric state to a polymeric state. The volume reduction due to this process can range from 1-5%. b. Hygroscopic Shrinkage: This is a long-term shrinkage caused by water absorption over time. Although not as significant as polymerization shrinkage, it can still impact the stability of the orthodontic appliance.

Measurement of Shrinkage: Various techniques are used to measure the shrinkage of ortho resin, such as: a. Linometer: This device measures the linear shrinkage by marking a line on the uncured resin, which then contracts upon curing, allowing the calculation of shrinkage percentage. b. Dilatometer: It measures the volumetric shrinkage by monitoring the change in the resin’s volume during polymerization. c. Micro-CT Imaging: This non-destructive technique provides a three-dimensional assessment of the resin’s shrinkage.

Consequences of Shrinkage: The shrinkage of ortho resin can lead to several clinical challenges: a. Inaccurate Bracket Placement: Excessive polymerization shrinkage can cause brackets to move away from their intended positions, leading to improper tooth alignment and compromised treatment outcomes. b. Marginal Gaps: Shrinkage-induced gaps between the ortho resin and tooth surface can result in microleakage and increase the risk of secondary caries. c. Bond Strength Reduction: Shrinkage stress can weaken the bond between the resin and enamel, making the appliance more susceptible to debonding.

Strategies to Mitigate Shrinkage Effects: Dentists and orthodontists employ various techniques to reduce the impact of shrinkage: a. Low-Shrinkage Resins: Manufacturers have developed ortho resins with reduced polymerization shrinkage to improve the overall treatment success. b. Incremental Layering: Applying the ortho resin in multiple thin layers and curing each layer separately helps minimize the cumulative effects of shrinkage. c. Light-Curing Techniques: Using light-curing methods with appropriate wavelengths and intensities can optimize the polymerization process and reduce shrinkage.

Future Perspectives: Research in dental materials is ongoing, and efforts are being made to develop novel ortho resins with even lower shrinkage values and improved mechanical properties. Advanced imaging and analytical techniques are also being explored to better understand shrinkage behavior and its impact on orthodontic treatments.

Ortho resin shrinkage is a critical aspect to consider in orthodontic treatments, as it can influence the accuracy of bracket placement, bond strength, and overall treatment success. Dental professionals must be aware of the causes and consequences of shrinkage and employ appropriate strategies to minimize its effects. Continuous advancements in dental materials science will undoubtedly contribute to the development of more reliable and efficient ortho resin materials in the future.https://en.wikipedia.org/wiki/Resin